Humbly Grove Energy, a wholly owned subsidiary of Petronas, operates the Humbly Grove Oilfield and Gas Storage Facility near Lasham in Hampshire. The gas storage facility has to respond to the business requirements of commodity trading and thus has to be in a state of readiness at all times to either import gas from the national grid or export from the store to the grid. The company recently upgraded its control and monitoring systems to ensure reliability and availability, the work was undertaken by Cougar Automation, based locally at Waterlooville, using the latest version of Wonderware InTouch provided by SolutionsPT

Humbly Grove Energy, a wholly owned subsidiary of Petronas, operates the Humbly Grove Oilfield and Gas Storage Facility near Lasham in Hampshire. The gas storage facility has to respond to the business requirements of commodity trading and thus has to be in a state of readiness at all times to either import gas from the national grid or export from the store to the grid. The company recently upgraded its control and monitoring systems to ensure reliability and availability, the work was undertaken by Cougar Automation, based locally at Waterlooville, using the latest version of Wonderware InTouch provided by SolutionsPT

The 10 billion cubic feet underground gas storage facility at Humbly Grove was built as an extension to an existing on-shore oil production plant. The store operates by taking natural gas from the National Grid Gas Transmission System through a 27km long, 24-inch diameter pipeline to the Humbly Grove oilfield. The gas is then pumped for storage into depleted oil reservoirs.

The original oil production and gathering plant at Humbly Grove has been in operation for over 25 years, whilst the gas storage facility commenced operations in 2005. Gas storage operations at Humbly Grove take gas from the grid when demand is low and resupply to the grid when the market demand is greater. The storage also provides valuable additional capacity to the system.

The original oil production and gathering plant at Humbly Grove has been in operation for over 25 years, whilst the gas storage facility commenced operations in 2005. Gas storage operations at Humbly Grove take gas from the grid when demand is low and resupply to the grid when the market demand is greater. The storage also provides valuable additional capacity to the system.

Accruing problems

The original 2005 control and monitoring scheme was designed using Wonderware InTouch and Rockwell PLCs with Pilz SIL3 equipment. Over the years, as the system was developed, it increasingly became unresponsive, mainly owing to network loading and non-optimised architecture. Support was proving difficult so Cougar Automation was requested to undertake a complete system review.

The main problem with the architecture was it had been extended and the data volume was overwhelming the control network infrastructure. The SCADA system was removed from the control network and a separate Ethernet system installed by adding Ethernet cards to the Rockwell controllers and used for SCADA purposes. This restored system responsiveness, but other work was needed to ensure reliable operation and to make the system more supportable. The need for availability and robustness was paramount and it was known that the existing system was not wholly reliable in switching from master to slave.

The main problem with the architecture was it had been extended and the data volume was overwhelming the control network infrastructure. The SCADA system was removed from the control network and a separate Ethernet system installed by adding Ethernet cards to the Rockwell controllers and used for SCADA purposes. This restored system responsiveness, but other work was needed to ensure reliable operation and to make the system more supportable. The need for availability and robustness was paramount and it was known that the existing system was not wholly reliable in switching from master to slave.

The Wonderware InTouch SCADA in use was Version 9 running on Windows XP, which required SolutionsPT provided DRAX (Dual Redundant Active X) to provide redundancy in this critical system by automating the changeover of tag servers. Although this had proven to be successful it was an extra aspect that needed support. Upgrading to the latest InTouch version would mean that DRAX was no longer needed as redundant operation is standard in InTouch and is enabled by a single mouse click. Transfers from master to slave are now not seen by operators as they are seamless and require little maintenance, any work that is needed can be undertaken without causing downtime. Kevin Baker, project manager, Cougar Automation, says: “The built-in redundancy function in the latest version of InTouch allowed us to readily configure resilience into the application.”

Upgraded to higher performance

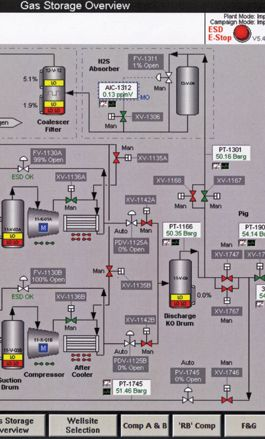

The update of InTouch was an automatic process with a report being generated about areas that needed manual intervention. This was minimal and Cougar Automation made some refinements to the SCADA displays for better clarity and aesthetic appeal. At the same time the operating system was upgraded to Windows 7. The visualisation of the plant is now clear and intuitive. This is important when a campaign is commenced (importing or exporting gas) as decisions involving the running of a large system have to be made quickly and correctly. This importance is illustrated by the plant’s ability to handle up to 8.5 million cubic metres of gas per day.

The hardware for the tag servers was supplied by Cougar Automation and procured from SolutionsPT’s hardware division, HardwarePT. These were two rack mounted units each running in RAID 1, further adding to the robustness of the whole system, and being pre-loaded with InTouch by HardwarePT. All the control room SCADA clients were changed to new machines with an array of flat screen displays.

System Integrity

The integrity of the site control system had to be validated, so following the upgrade Cougar Automation produced a ‘cause and effect’ testing system. The site has comprehensive emergency shutdown procedures which are executed from the control room using dedicated hardwired systems.

Phill Allen, Humbly Grove Energy C&I engineer: “Cougar Automation has provided us with a system that is much more resilient and responsive”. Allen adds that Wonderware InTouch was their preferred system as it provided full insight into their facility and a clear overview display of the facility and detailed alarms and reports. Summarising, Allen says: “The system has provided peace of mind at many levels, most importantly being that it is a well supported.”

Petronas

petronas.com.my

Cougar Automation

www.cougar-automation.com

SolutionsPT

solutionspt.com

wonderware.co.uk