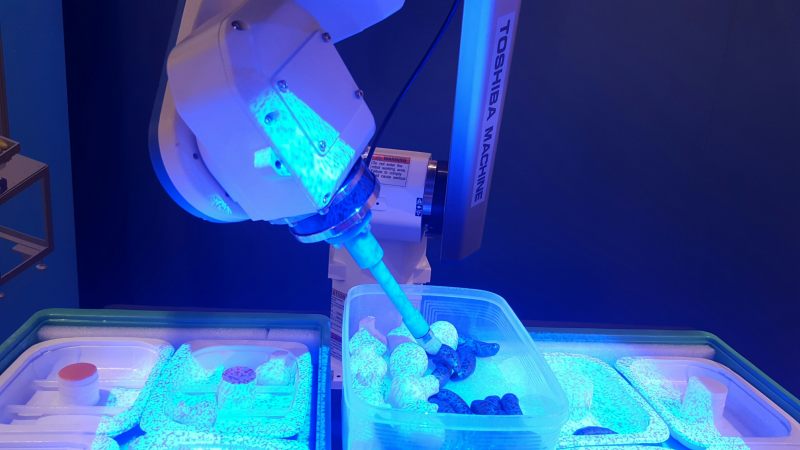

TM Robotics, in partnership with Toshiba Machine, launched Toshiba Machine’s TSVision3D software at the recent Automatica 2016 robotics focused trade fair which took place in Munich on 21-24 June. TSVision3D was developed and designed so anyone can understand and use it—a stark contrast to previous 3D vision technologies in the industry that required a high level of expertise and were difficult to use. Carefully created as an optimised balance between processing speed and accuracy, companies in industries such as food preparation, pharmaceutical, and order fulfillment now have access to usability-oriented support software that enables system integrators to easily automate bulk picking.

TM Robotics, in partnership with Toshiba Machine, launched Toshiba Machine’s TSVision3D software at the recent Automatica 2016 robotics focused trade fair which took place in Munich on 21-24 June. TSVision3D was developed and designed so anyone can understand and use it—a stark contrast to previous 3D vision technologies in the industry that required a high level of expertise and were difficult to use. Carefully created as an optimised balance between processing speed and accuracy, companies in industries such as food preparation, pharmaceutical, and order fulfillment now have access to usability-oriented support software that enables system integrators to easily automate bulk picking.

While human workers can look at a jumbled bin full of parts and immediately identify the best way to pick up items based on their shape and position, avoiding the edge of the bin as they reach inside, the complexities of automating these actions have been prohibitive until recently. Now, with TSVision3D, the system incorporates two integrated, high-speed stereo cameras that are capable of 30 frames per second for continuous, real-time 3D images. The camera manages image capture, processing and parallax operations to identify items’ positions, and the vision software adds easy model registration without requiring complex CAD data.

“This new approach to 3D vision combines the latest vision system technologies and software to overcome stumbling blocks previously experienced with 2D vision systems,” said Nigel Smith, CEO of TM Robotics. “TSVision3D makes automated bin-picking a reality, even for smaller volume and highly variable applications. Our customers are thrilled they finally have this option, and we’re looking forward to helping them get it installed.”

In support of the TSVision3D launch, TM Robotics has also written a white paper on automating bin-picking as a cost-effective option. Click HERE to read more.

Other Toshiba Machine robots TM Robotics demonstrated at Automatica included:

- The High Speed SCARA THP550. This will work in tandem and synchronize with a Toshiba Machine linear actuator. It’s a high-speed demonstration that simulates insertion and synchronization.

- TV800 6-axis robot. This exhibit simulates wine pouring while showing the full dexterity of movements of the Toshiba Machine 6-axis robot range:https://www.youtube.com/watch?v=TiwBGdrSkKs.

- TVL500, the small 6-axis robot, and the THL300 SCARA. This is an intricate handling demonstration that highlights the flexibility of the award winning 6-axis robot and the movements of the cost-effective THL SCARA range: https://www.youtube.com/watch?v=gjT5jZhH76E.

The TV and TVL Series are a cost-effective 6-axis robot range from 600mm to 1000mm in arm length that can handle up to 10kgs of payload. With the THP demo, the controller technology simplifies the process of adding a sliding fifth axis to the SCARA robots. This enables end users to extend the range of a SCARA robot or use the modified machine to transfer product from one workstation to another without human intervention or the addition of any non-robot automation technologies.