At EMO Hannover 2013, Hi-Tech Automation will feature its CR Machine Tending Robot with an all electric FANUC S-2000i injection moulding machine and two robot machine loading systems featuring the newly introduced FANUC ROBODRILL a-D21 Series machining centre.

At EMO Hannover 2013, Hi-Tech Automation will feature its CR Machine Tending Robot with an all electric FANUC S-2000i injection moulding machine and two robot machine loading systems featuring the newly introduced FANUC ROBODRILL a-D21 Series machining centre.

Developed specifically for high speed handling, the Hi-Tech Automation CR Range is well suited to injection moulding and machine tending applications. Using FANUC’s intelligent Power Motion i-A control platform and CNC drives, it provides high levels of accuracy with straight line and linear interpolation as standard.

Application specific functions, provided through the easy to use i-Pendant, include platen following to reduce mould open time, and collision avoidance to guard against operator error during tool set-up.

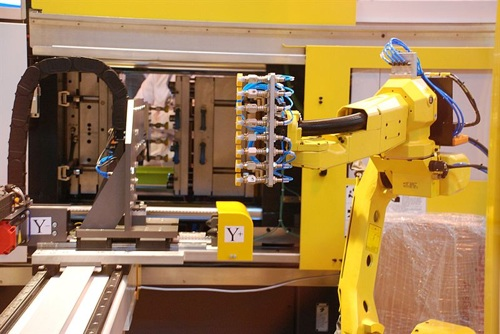

Loading and unloading a cylinder head into a FANUC ROBODRILL a-D21 Series machining centre will be an R-1000 i-A robot, FANUC’s 100kg payload workhorse well suited where fast and accurate handling and positioning of product is required. The system will also illustrate FANUC’s 2D vision using standard integrated vision software.

Also integrated to a ROBODRILL a-D21 Series machining centre will be a LR Mate-200iD robot loading and unloading small components. Designed for 24/7 high duty cycles, the ROBODRILL and LR Mate combination is well suited for batch production where the system can effectively be operated unmanned.

A strategic partner of FANUC, Hi-Tech Automation brings in-depth application specific experience to the partnership, allowing customers to benefit from proven integration of their high value automation assets.