Digital data printed directly on products allows for complete component traceability even in high-volume production environments and the use of laser marking technology guarantees extremely low error rates in this process

Digital data printed directly on products allows for complete component traceability even in high-volume production environments and the use of laser marking technology guarantees extremely low error rates in this process

Highly efficient code reading and tracking with modern imaging systems is every bit as important to the production process as the reliable printing of barcodes and Data Matrix codes and of brand-related components such as logos and product and company names. However, the performance and flexibility of the hardware installed to facilitate this process is entirely dependent on the quality and functionality of the image processing software used.

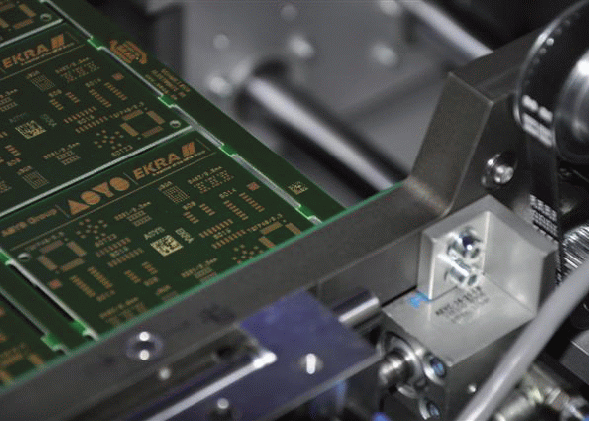

In order to meet the challenge of complete component traceability, one of the pioneering companies in the field of laser marking technology, ASYS Automatisierungssysteme of Dornstadt, Germany, incorporates Cognex VisionPro vision software into its prize-winning INSIGNUM 2000 laser marking system.

Technologies for the future

The ASYS Group is a group of eight companies, including ASYS Automatisierungssysteme, EKRA Automatisierungssysteme and ASYS Solar. In Dornstadt, ASYS Automatisierungssysteme develops and manufactures handling, marking and blank cutting systems, as well as assembly and special systems. Since its foundation in 1992, the high-tech company has grown very fast and now has over 800 employees. The springboard for the company’s entrepreneurial success has been the development of innovative solutions that play a leading role in worldwide technology markets. Recently, the INSIGNUM series of laser marking system for the processing of printed circuit boards, which use the latest in image processing, including the Cognex VisionPro vision software, have led the charge to set new standards.

Speed through deflecting mirror

ASYS first deployed VisionPro in the high-speed model of the INSIGNUM 2000 Laser series. This machine marks a complete marking area with a fixed laser and reads out the Data Matrix code by camera and mirror deflection. The INSIGNUM 2000 Laser reads up to 20 codes in less than 15 seconds, including handling and checking. The laser and reading unit are mounted in a fixed position above the transport system and each printed circuit board to be marked is brought quickly and precisely into position.

ASYS first deployed VisionPro in the high-speed model of the INSIGNUM 2000 Laser series. This machine marks a complete marking area with a fixed laser and reads out the Data Matrix code by camera and mirror deflection. The INSIGNUM 2000 Laser reads up to 20 codes in less than 15 seconds, including handling and checking. The laser and reading unit are mounted in a fixed position above the transport system and each printed circuit board to be marked is brought quickly and precisely into position.

The key component of the system is the deflection unit in which the camera is coupled into the ray path of the laser. This enables a marking area of 350 x 350mm to be processed without resorting to a mechanically driven system of axes. For marking on both sides, an optional turning station can be incorporated. For still greater speed, a separate laser can be installed to mark the circuit boards from beneath.

The power beneath the surface

In the INSIGNUM 2000, the combination of laser technology and the VisionPro software offers significant advantages compared to scanner techniques. “The latest vision systems don’t just enable us to read out codes and characters for complete traceability,” explains Swen Nothjunge, marking systems product manager for ASYS, “we can also recognise registration marks and identify printed boards from their layout.” The comprehensive VisionPro tool library never ceases to offer the ASYS Group’s developers new and flexible application possibilities.

One of the ASYS Group’s developers’ conditions in the selection of the vision software was easy and reliable integration of the ASYS software, ‘ASYMARK’. VisionPro had the tools needed to integrate the vision software with the internal automation software without any problem. The users only need to work with one user interface. In systems from other manufacturers, several applications must be opened and manipulated for the various test and work steps. The easy integration offered by VisionPro eliminated this burdensome process from the INSIGNUM series systems. “The VisionPro tools make the operation of our laser marking systems even simpler,” says Nothjunge. “The customer does not need different software for scanner, laser and printer but can operate all three from a single user interface.”

Intelligent tools pay off

The multiplicity of the tools and their unusual ease of integration have driven VisionPro to the peak of modern vision systems. The drag and drop connection between the individual tools, for example, permits speedy transfer of values, results and images. The settings simplify dynamic positioning by intelligent software set-up. Reusable sets of tools that users themselves define, if need be, shorten development times. VisionPro is intelligent enough to ignore uncritical changes in appearance and concentrate on the critical characteristics on which product acceptance depends. Since its tools require no image preprocessing overhead, the application development time is shortened and the life-cycle costs for the company are reduced.

Cognex UK

T: 01327 856040