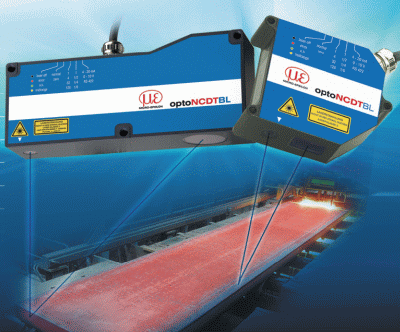

Micro-Epsilon has launched its Blue Laser Sensor said to offer significant benefits in measuring the position or displacement of red-hot glowing metals and also translucent targets. The optoNCDT 1700BL series of Blue Laser Sensors operate on the laser triangulation measuring principle and use blue (violet) laser technology.

They are suitable for measurements on hot, glowing metals, particularly in hot steel processing applications, as well as for measuring organic materials such as skin, foodstuffs, plastics, veneers and wood.

The wavelength of the blue laser offers certain advantages. With red, glowing objects, a conventional red laser has a high signal interference from the object surface, because it emits the same or very near wavelengths of light as the red laser.

The blue laser works at a wavelength of 405nm, far from the red part of the visible spectrum meaning it is easier to filter this type of emitted light from the object, which ensures stable signals. The blue laser measures well on glowing metals and ceramics, an advantage when measuring wear or deformation of automotive brake discs under load. There are also benefits when measuring against translucent objects such as organic materials, paper, some plastics and wood veneers.