Saint-Gobain Performance Plastics is helping OEMs to meet the demands for automotive friction control and manufacturing performance with its range of innovative composite components.

Saint-Gobain Performance Plastics is helping OEMs to meet the demands for automotive friction control and manufacturing performance with its range of innovative composite components.

The global automotive market is putting increasing demands on original equipment manufacturers (OEMs) to produce high-performance parts that are affordable and long-lasting. Saint-Gobain Performance Plastics is helping OEMs meet these demands with its range of innovative NORGLIDE composite bearings and RENCOL tolerance rings.

Suitable for powertrain, chassis, and interior and exterior vehicle applications, Saint-Gobain’s composite bearings and tolerance rings are said to optimise component manufacturing and driving performance and comfort for the end-consumer.

The trend towards increasing efficiencies within the powertrain and chassis components helps to bring about savings in fuel and meeting carbon dioxide (CO2) reduction targets. NORGLIDE composite bearings and RENCOL tolerance rings allow the benefits of increasing efficiencies of individual components to be realised by using the materials to help improve friction control and reducing noise, vibration and harshness (NVH).

Controlled friction values

NORGLIDE composite bearings incorporate a thick layer of self-lubricating liner made from polytetrafluoroethylene (PTFE), offering controlled friction values that perform under axial and radial stress to improve NVH reduction. The spring-like qualities of RENCOL tolerance rings ensure a tight fit between bearings, shafts and housing. Protrusions running along the circumference of RENCOL tolerance rings efficiently absorb NVH transmitted through mechanical joints within a vehicle’s chassis and powertrain.

Vehicle applications

Vehicle applications

Saint-Gobain recently demonstrated a steering yoke with NORGLIDE composite bearings. By using a thick layer of PTFE, NORGLIDE composite bearings reduce friction in the steering yoke, improving steering feel and response.This enhances a motorist’s ability to feel the road surface and ultimately improves driving experience.

Saint-Gobain has also shown a car seat armrest fitted with RENCOL tolerance rings to enhance torque control. By incorporating a certain amount of friction, arm rests stay in place and are prevented from falling down. The controlled friction ensures a quality feel and consumer perception of performance and luxury.

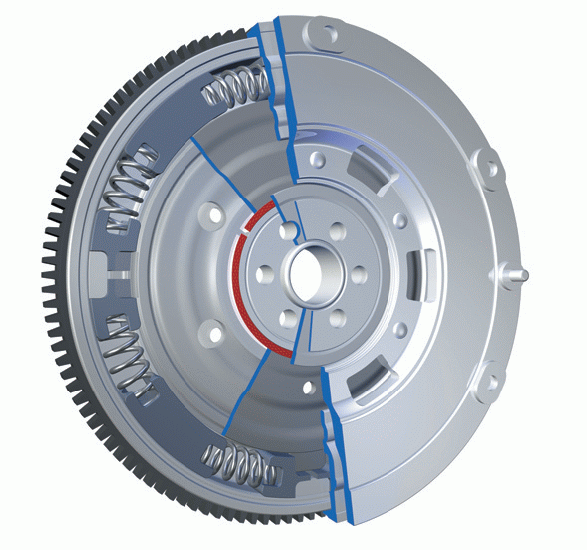

By incorporating NORGLIDE composite bearings, dual mass flywheels dampen the vibrations from a car’s engine and prevent vibrations from reaching the gearbox. This results in a more comfortable driving experience for motorists.

By incorporating PTFE in its NORGLIDE composite bearing, Saint-Gobain is able to control torque in hinges to exact specifications. NORGLIDE composite bearings can be used on metal frames without compromising painting operations.

“Automotive OEMs are looking for custom designed, innovative components that improve efficiency and offer long-lasting durability. Saint-Gobain is meeting OEM needs while ensuring improved driver comfort and enjoyment,” says Chris Needes, global market manager automotive chassis and powertrain, Saint-Gobain Performance Plastics.

Saint-Gobain Performance Plastics

T: 0117 9381700