Marco has released what it claims is the first ‘off the shelf’ manufacturing execution system aimed at the food and beverage sector

Marco has released what it claims is the first ‘off the shelf’ manufacturing execution system aimed at the food and beverage sector

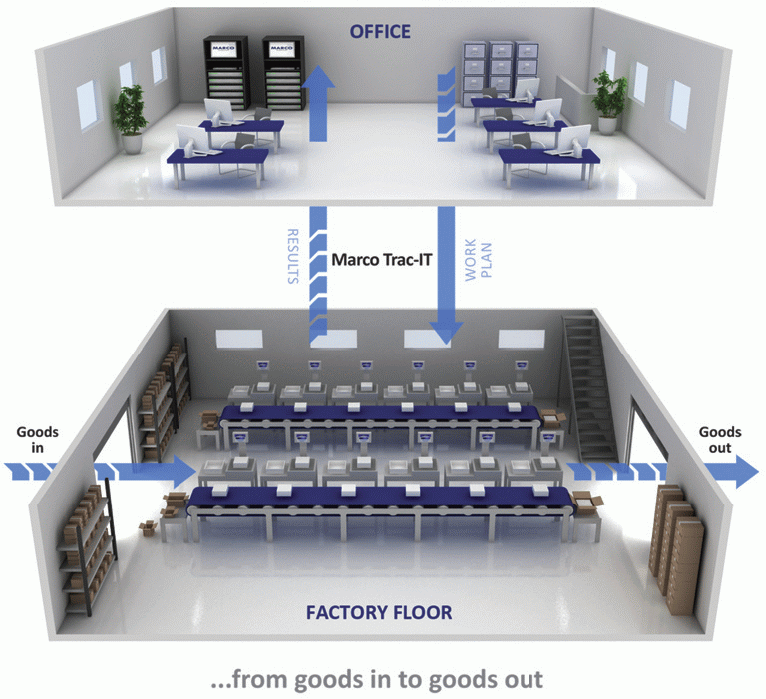

Manufacturing Execution Systems (MES) bring important real time control to manufacturing processes within the food sector, unlocking the potential of ERP and allowing systems to react to actual information rather than historic data. They coordinate dynamic processes across the plant floor, improving productivity and profitability. However, these systems can be complex, expensive and very time consuming to implement; requiring significant input from both client and supplier. Reality shows that it can take years to develop a satisfactory, fully integrated working system.

It is quite clear that manufacturers want the control, functionality and profit improvements that an MES can deliver, but ideally without the hurdles and costs associated with the development and implementation. Marco has found time and time again that the following comments have become common feedback from managers within the food manufacturing industry:

“We won’t be able to get the funds needed to install a full ‘goods in to goods out MES’ on the factory floor, regardless of the return of investment.”

“In this economic climate we don’t have the in-house resource necessary to fully specify and implement a factory wide system.”

“We can’t wait 18 months to two years to gain the cost savings that we know an MES would deliver.”

To overcome these barriers, Marco has developed what it claims is the world’s first ‘off the shelf’ MES solution called Trac-IT MES.

Control requirements

The culmination of thousands of man hours of software generation over the past 25 years, this MES solution is claimed to satisfy more than 80 per cent of the manufacturing control requirements for ready meal producers. This starts at goods-in right through recipe formulation, meal assembly, stock control, packing and labelling and finally on to goods out.

Any business which converts raw materials into finished product will have unaccountable losses unless they have an effective manufacturing execution system (MES) in place.” – Neil Drew, Unilever Ice Cream

Off the shelf package

Marco has used its wealth of factory profitability experience, gained through working with major brands around the world, to bring together essential elements of a universal MES solution in a single ‘off the shelf’ package.

The system can be installed into existing plant and brings immediate improvements to the manufacturing environment.

As appropriate, once the Trac-IT MES module is implemented, the client can choose to work with Marco to further expand the versatility of the system in key plant areas.

Key benefits of Marco Trac-IT MES are said to be:

- Unique ‘off the shelf’ MES functionality

- 75 per cent less time to implement compared with normal MES solutions

- 75 per cent less cost – 80 per cent functionality

- Minimum plant disruption to install

- Improved productivity

- Improved product consistency and quality

- Optimised raw material usage – improved stock control

- Minimised waste

- Eradication of unaccountable losses

- Full electronic traceability throughout the plant

- Improved line control – 100 per cent labelling accuracy

The Trac-IT MES module forms part of Marco’s Factory Profitability Portfolio which includes: Trac-IT Yield Control Module, Trac-IT Recipe Formulation Module, Trac-IT Line Control Module, Trac-IT Waste Control Module and Trac-IT ‘e’ Weighing Module.

Marco

T: 01342 870103