Oden Technologies, the intelligent industrial automation provider, has announced what it claims is the industry’s first end-to-end Machine Learning (ML) and Artificial Intelligence (AI) framework for manufacturing.

Oden Technologies, the intelligent industrial automation provider, has announced what it claims is the industry’s first end-to-end Machine Learning (ML) and Artificial Intelligence (AI) framework for manufacturing.

With a novel, patent-pending infrastructure spanning both the cloud and the edge, the framework allows manufacturers to deploy mission-critical ML and AI applications to avoid machine failure, eliminate waste, and optimise production in real-time.

Despite the increasing adoption of Machine Learning and AI across other industries, their applications in process manufacturing have been limited. The complexity and specificity of manufacturing processes have traditionally demanded heavily customised solutions developed by internal data science teams.

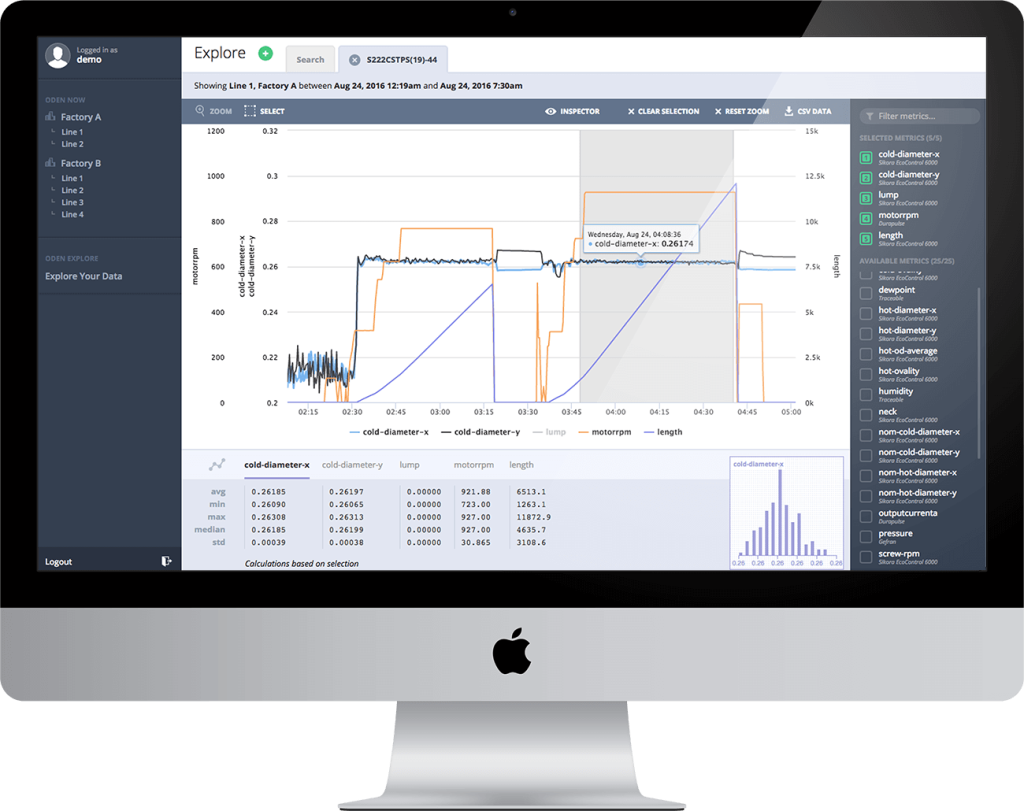

Oden’s production-ready ML and AI framework is tailored specifically for manufacturing processes. It integrates ML algorithms and data science tools with both structured and unstructured data from machines, operator inputs, QA, work orders, environmental monitors, and product specs. The hybrid cloud and edge infrastructure delivers the power of the cloud without compromising the requirements of mission critical applications.

The framework can be used to continuously monitor the manufacturing process to predict quality and machine health, detect abnormal behaviour, and provide recommendations on recipes and process settings. Manufacturers can leverage the Oden framework to rapidly prototype and test new ideas for process monitoring and optimisation, and more importantly, deploy them directly into their mission critical operations with little to no overhead.

“Today’s launch marks the first step to delivering intelligent industrial automation to our customers,” said Willem Sundblad, co-founder and CEO, Oden Technologies. “The future of manufacturing demands intelligent systems that can provide real answers to the production issues manufacturers have been asking for decades. Only then can they achieve perfect production, with zero waste.”

The Oden platform provides continuous visibility into factory operations and processes, with customers seeing improvements such as a 20 per cent increase in monthly output and 50 percent decrease in total scrap, resulting in millions of dollars in savings and additional revenue each year. Dr Deepak Turaga, VP of Data Science at Oden Technologies, believes that the open and extensible nature of this ML and AI framework will accelerate such gains significantly.

“One-size-fits-all approach to Machine Learning and AI will never deliver on its full potential,” he commented. “That’s why our goal is to provide customers with the best-in-breed foundational ML and AI applications tailored for manufacturing, and the framework tools to easily extend and adapt them to their specific requirements and processes.

The ultimate benefits of Oden’s ML and AI framework extend beyond improving current production processes and operational efficiency. By integrating structured and unstructured data, supported by best of breed ML tools, it can be used to capture both implicit and explicit process know-how. In the future, this will allow manufacturers to leverage the system in bridging their talent skills gap.

About Oden

Oden Technologies is the intelligent industrial automation company empowering manufacturers to achieve perfect production by providing complete visibility into all the production processes in real-time. The Oden platform wirelessly collects data from any machine, integrates it with third-party systems, and delivers instantaneous insights leading to effective quality control, timely maintenance and lower machine downtimes, optimised operations, and higher customer satisfaction. Oden investors include Atomico, EQT Ventures, Inbox Capital, and LocalGlobe.