Seismometers are among the most sensitive instruments ever invented. They are known mainly for their use in recording earthquakes, but they can also detect bad weather and the corroding parts of building foundations.

Seismometers are among the most sensitive instruments ever invented. They are known mainly for their use in recording earthquakes, but they can also detect bad weather and the corroding parts of building foundations.

Swiss ballscrew and leadscrew manufacturer, Eichenberger Gewinde, has developed a miniature threaded spindle with practically zero tolerance, which has been shown to play a vital role in the fine adjustment of the three pendulums in a seismometer.

In the 1970s the geophysicist G. Streckeisen began developing seismometers. He built instruments which set new standards of sensitivity. Streckeisen’s seismometer incorporated three balancing pendulums whose sensitivity was so high that even the impact of waves on the Atlantic coast were recorded as far away as Switzerland. Since 2010, two employees have continued to run the company – the mechanical engineering graduate Lutz Wiesner and the electronics engineer Robert Freudenmann.

As many electronic and mechanical components had been discontinued by component suppliers, Wiesner and Freudenmann had to develop new prototypes. Using Streckeisen’s proven principle of three pendulums and a feedback system, in conjunction with modern components, they built an instrument that seamlessly followed its successful predecessor.

The normal frantic pace of producing new designs does not suit such a sensitive device as a seismometer. This application requires calmness and patience, as any introduced stress lives on in quasi form in the device, later leading to a deterioration of the output signals. This also applies to mechanical components under tension where the screws have been excessively tightened, as well as in parts from component suppliers.

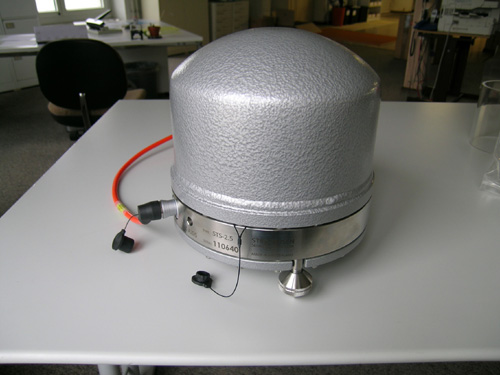

The concept of ‘calm’ becomes a constant companion, and assembly at Streckeisen proceeds accordingly. In operation, the seismometer should be able to record the slightest movement of so-called ‘ground noise’ of our Earth. Here its enemies are different vibrations caused by people, cars, lorries or trains. The weather and even the moon contribute to unwanted signals.

The Streckeisen seismometer consists in principle of three individual sensors arranged at 120º to the others. Each sensor contains a precisely balanced, upside-down diagonal pendulum that is maintained in its central position by means of a temperature-compensated spring and a feedback system. The pendulum mounting is absolutely free of play. This way the capacitive travel sensor records the pendulum position to an accuracy of a few atoms wide. Control electronics and a coil provide the corresponding restoring force.

The Streckeisen seismometer consists in principle of three individual sensors arranged at 120º to the others. Each sensor contains a precisely balanced, upside-down diagonal pendulum that is maintained in its central position by means of a temperature-compensated spring and a feedback system. The pendulum mounting is absolutely free of play. This way the capacitive travel sensor records the pendulum position to an accuracy of a few atoms wide. Control electronics and a coil provide the corresponding restoring force.

With the help of analogue electronics the three sensor signals are converted into values for the X, Y and Z axes. These analogue signals come via a cable connection into a digitalisation box that logs all data before forwarding it to an earthquake centre by radio, telephone or satellite link.

The device must be aligned exactly to the east prior to use at the appropriate location. The seismometer is manually adjusted horizontally with the aid of a level. As every location is unique with regards to temperature and gravitational force, fine adjustment of the three pendulums is always necessary and occurs automatically. For this purpose the travel sensor determines the pendulum position and corrects the pendulum balance with the aid of an adjusting mass. The adjusting mass is pushed along a rolled Eichenberger threaded screw until the pendulum exactly occupies the central position. Decisive factors in the use of an Eichenberger threaded screw with two ground ends of h6 quality are the surface quality and the thread geometry. Even the position of the rolled thread arranged on the middle of the longitudinal axis has to satisfy the highest demands for tolerance. In addition, the substance has to be absolutely non-magnetic. All of this is done with a screw with a diameter of just 4mm.

For nearly 60 years Eichenberger Gewinde has specialised in the manufacture of threads. The focus today is on the rolling of threads by ‘cold forming’ in the manufacture of ball screws and high-helix lead screws. By using the most modern production methods and through the development of new applications – such as the thread manufactured specially for Streckeisen – Eichenberger is supporting customers with a myriad of different innovations.

For nearly 60 years Eichenberger Gewinde has specialised in the manufacture of threads. The focus today is on the rolling of threads by ‘cold forming’ in the manufacture of ball screws and high-helix lead screws. By using the most modern production methods and through the development of new applications – such as the thread manufactured specially for Streckeisen – Eichenberger is supporting customers with a myriad of different innovations.