When AIM, an aerospace component manufacturer, changed its business model from large production runs to intricate batch manufacture, it invested in a series of five-axis CNC machining centres and CAD/CAM software from Open Mind Technologies.

When AIM, an aerospace component manufacturer, changed its business model from large production runs to intricate batch manufacture, it invested in a series of five-axis CNC machining centres and CAD/CAM software from Open Mind Technologies.

The Clevedon-based company has been involved in aerospace manufacture since receiving its first order from Airbus in 1984 and it has subsequently evolved into a prestigious aerospace subcontractor operating out of five units and employing 40 staff members.

Managing director, Rob Kendall says in order to evolve to meet aerospace demands, Aim has a diverse range of machines now including four, five-axis machining centres. Three Mikron and one Hedelius five-axis machine were acquired and then loaded with high specification tooling from Iscar. But despite the investment, there was still a bottleneck with part programming.

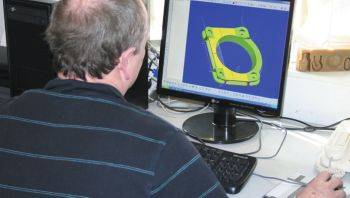

AIM then acquired two seats of Open Mind’s hyperMILL system. Kendall says: “Our five programmer’s confidence in hyperMILL and our five-axis capability is growing and we are moving more parts from our three-axis machines to five-axis daily. Our production times are up to 50 per cent faster on our five-axis machines and while set-ups and the elimination of second operations is a major contributor, it is hyperMILL that has enabled us to move parts across with confidence.”

AIM then acquired two seats of Open Mind’s hyperMILL system. Kendall says: “Our five programmer’s confidence in hyperMILL and our five-axis capability is growing and we are moving more parts from our three-axis machines to five-axis daily. Our production times are up to 50 per cent faster on our five-axis machines and while set-ups and the elimination of second operations is a major contributor, it is hyperMILL that has enabled us to move parts across with confidence.”

“Lights out machining is gradually increasing. This rise in unmanned machining is credit to the confidence in hyperMILL and its remarkable collision avoidance. The hypermill system has enabled us to improve cycle times by upwards of 50 per cent, reduce programming times, and improve confidence, surface finishes and product quality. It has also drastically cut finishing operations like deburring.”