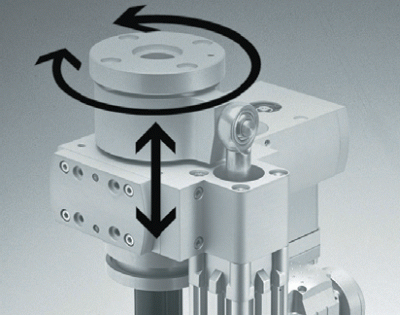

Festo has launched a compact integrated motion control subsystem for automation applications that provides machine builders with a flexible means of providing programmable rotary and linear movement. Suitable for parts handling and positioning applications, the EHMB module features a decoupled design, enabling the rotary and lifting movements to be controlled independently, for fast, accurate positioning.

Festo has launched a compact integrated motion control subsystem for automation applications that provides machine builders with a flexible means of providing programmable rotary and linear movement. Suitable for parts handling and positioning applications, the EHMB module features a decoupled design, enabling the rotary and lifting movements to be controlled independently, for fast, accurate positioning.

The subsystem can perform similar types of loading and unloading movements as many SCARA robots, with comparable performance, but at less than half the cost.

Users may also tailor the price/performance of the motion subsystem by choosing to use a motor and electrical actuator for the two axes, or a motor and pneumatic cylinder. Festo’s modular EHMB design can be configured with a range of the company’s positioning cylinders, motors and controllers.

Festo offers a choice of two EHMB modules, to simplify application matching. The smaller size 20 model can accommodate payloads of up to 3kg, generate more than 3Nm of torque and handle moments of inertia as high as 30kg/cm/cm. The larger size 25 model is suited to stationary use, such as in loading, unloading and stacking applications. Capable of accommodating payloads as high as 5kg, it can generate 8.8Nm of torque and handle moments of inertia up to 100kg/cm/cm. EHMB modules offer fast and accurate lifting and rotating capabilities with linear speeds up to 500mm/s.