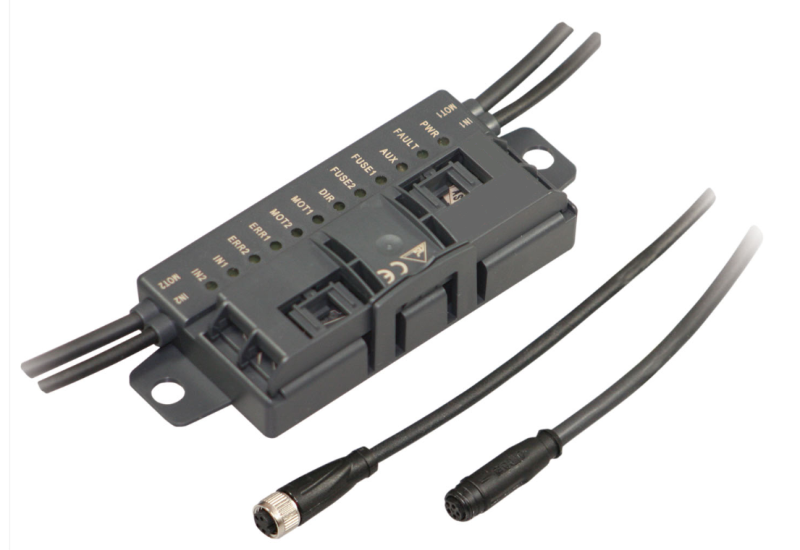

The new G20 AS-i motor module provides direct control over the direction of rotation, start/stop, eight different speeds (remotely adjustable), and up to eight start-up ramps and deceleration ramps to prevent slip. The robust housing of the G20 AS-i motor module is less than 30mm tall so that it can be easily integrated in the side profile of the conveyor and can deliver up to 5A per roller motor and 0.5A for the sensors. The motors are monitored by two feedback inputs for diagnostic purposes. It has direct connections for two DC roller motors and two sensors (perfect for zero pressure applications).

The new G20 AS-i motor module provides direct control over the direction of rotation, start/stop, eight different speeds (remotely adjustable), and up to eight start-up ramps and deceleration ramps to prevent slip. The robust housing of the G20 AS-i motor module is less than 30mm tall so that it can be easily integrated in the side profile of the conveyor and can deliver up to 5A per roller motor and 0.5A for the sensors. The motors are monitored by two feedback inputs for diagnostic purposes. It has direct connections for two DC roller motors and two sensors (perfect for zero pressure applications).

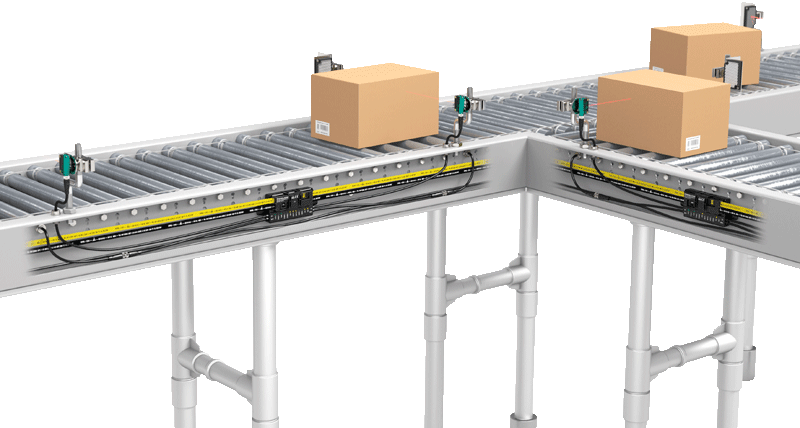

The rapid installation technique of the AS-i cable means that conveyor sections can be pre-assembled and connected in segments with sensors and drives. These segments can then be easily installed on site needing only the flat cable to be inserted and connected as a final, tool-free step. The one-piece housing has a swiveling lid into which the flat cable can be inserted in two orientations with reverse polarity protection.

Twelve multi-color LEDs indicate the IO status of the module, as well as other diagnostic information regarding communication and motor operation.

Twelve multi-color LEDs indicate the IO status of the module, as well as other diagnostic information regarding communication and motor operation.

Another G20 module version is also available that completes this material handling solution and features three digital inputs and outputs. It is used to control stoppers, valves, switches, or jacks. The module is available in the same housing with direct connection and can be integrated in the mounting strip.