Kistler Instruments’ sensors are at the forefront of sensing technology supported by high precision control and monitoring systems.

KiTorq Intelligent Torque Measuring Flange

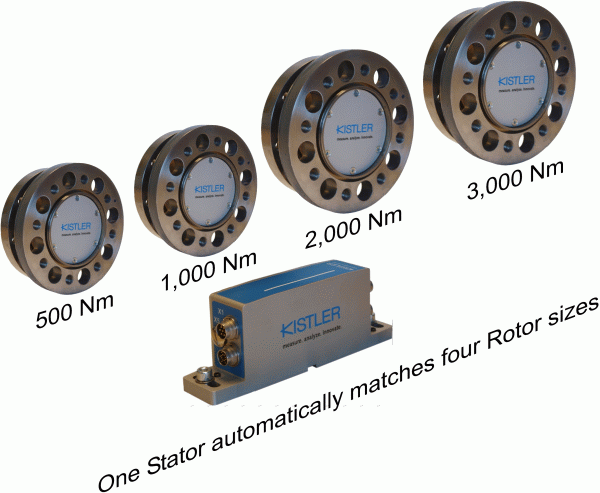

The Kistler KiTorq torque measuring flange system operates without an antenna ring and has standard flange geometry conforming to ISO7646 for easy installation. The open stator design allows faster installation whilst minimising the risk of damage and easier visual inspection during testing. The universal, intelligent stator may be used with any KiTorq rotor of the same speed rating for greater operational flexibility.

The Kistler KiTorq torque measuring flange system operates without an antenna ring and has standard flange geometry conforming to ISO7646 for easy installation. The open stator design allows faster installation whilst minimising the risk of damage and easier visual inspection during testing. The universal, intelligent stator may be used with any KiTorq rotor of the same speed rating for greater operational flexibility.

A choice of 500, 1,000, 2,000 or 3,000 Nm measuring ranges is available each with an accuracy class of 0.05% of range. The system has an excellent torque signal bandwidth of up to 10 kHz and a 60 pulses per revolution speed output.

A single, intelligent stator can be used with any KiTorq rotor of the same speed rating and will automatically recognise the rotor measuring range. This minimises hardware investment as one stator may be used with rotors of differing ranges for different applications. Installation is simplified by the contactless, digital telemetry that does not require an antenna ring.

Value for money torque sensor is robust and maintenance free

The Type 4520A contactless torque sensor from Kistler costs less than £1,500, the same as many slip-ring types, and is exceptionally robust and very low maintenance. Non-contact, frequency modulation signal transmission, used to transmit the torque signal from the rotating shaft, virtually eliminates wear leading to a long life, even in continuous use applications. A TTL speed signal at 60 pulses/rev. and an external 100% range check input are provided as standard.

The Type 4520A contactless torque sensor from Kistler costs less than £1,500, the same as many slip-ring types, and is exceptionally robust and very low maintenance. Non-contact, frequency modulation signal transmission, used to transmit the torque signal from the rotating shaft, virtually eliminates wear leading to a long life, even in continuous use applications. A TTL speed signal at 60 pulses/rev. and an external 100% range check input are provided as standard.

Ten models are available with rated torque from 1 to 1,000 Nm each with industry standard ±10 V signal output. Class 0.5 accuracy at speeds of up to 10,000 rpm is combined with a maximum overload capacity of 150%.

The Kistler torque sensor range is ideal for static and dynamic torque measurement in production, quality control and research and development applications.

The new maXYmos BL – A complete measuring chain for under £2,000

The latest version of the Kistler maXYmos BL process monitoring and product testing system is the basis of a complete XY measuring chain costing less than £2,000, including sensors. Since its launch, the maXYmos BL system has proved to be a cost-effective method of monitoring a wide range of manufacturing processes, especially joining, assembly, and product testing. Monitoring the relationship between force and distance provides an accurate evaluation of any variation in a production process or product performance compared with a known optimum.

The latest version of the Kistler maXYmos BL process monitoring and product testing system is the basis of a complete XY measuring chain costing less than £2,000, including sensors. Since its launch, the maXYmos BL system has proved to be a cost-effective method of monitoring a wide range of manufacturing processes, especially joining, assembly, and product testing. Monitoring the relationship between force and distance provides an accurate evaluation of any variation in a production process or product performance compared with a known optimum.

The new version adds envelope curve evaluation as standard to further enhance the performance of this versatile and compact monitor. During setup, the band of the envelope curve automatically wraps around the outside contour of a previously measured bundle of curves evaluated as “Good”. New PC software allows direct transfer of the test data to a PC and provides an easy to use method for displaying, measuring and analysing measurement curves.