A UK-based machine builder has reported positive feedback from its customers after installing Beijer iX Panel HMIs on an industrial oven and a food handling and conveyor system. Based in Haverhill, Suffolk, AMP Systems & Control specialises in the design and build of special purpose food handling and conveyor systems, including special purpose meat handling conveyors and stackers.

in Haverhill, Suffolk, AMP Systems & Control specialises in the design and build of special purpose food handling and conveyor systems, including special purpose meat handling conveyors and stackers.

Although the machine building division of AMP was only set up earlier this year, the engineers possess many years of experience in the design and build of machines for the UK food processing industry.

Richard Taylor, systems design engineer at AMP Systems & Control comments: “When we set up the new machine building division, we began to look at which HMIs were available on the market that we could install on our machines.

“Four months ago, a local customer approached us and specified that he wanted two Beijer HMIs on his meat handling machine. I therefore attended a Beijer one-day training course at M.A C Solutions, the UK distributor for Beijer HMIs. This course was very interesting and was a real eye-opener for me in terms of what the HMIs were capable of. The new iX Panel series in particular offered so much more control functionality and open connectivity than I had seen before.”

According to Taylor, one of his recent customers needed a control and automation system in order to help the company solve a critical issue surrounding its industrial ovens. The ovens, which are used for cooking meat products, have a door on each side, which operators use to enter and exit the oven.

As the ovens are located in the centre of production lines, operators were using ovens as a short cut to access other areas of the production line downstream. This was a problem because if two operators opened both doors of the oven simultaneously during the cooking process, there was a genuine risk of meat becoming contaminated. A control and automation solution was therefore required. As Taylor puts it: “The customer supplies meat to major supermarkets, so it was absolutely critical that we helped them solve this contamination issue.”

As the ovens are located in the centre of production lines, operators were using ovens as a short cut to access other areas of the production line downstream. This was a problem because if two operators opened both doors of the oven simultaneously during the cooking process, there was a genuine risk of meat becoming contaminated. A control and automation solution was therefore required. As Taylor puts it: “The customer supplies meat to major supermarkets, so it was absolutely critical that we helped them solve this contamination issue.”

The solution provided by AMP included two Beijer iX Panel T60 HMIs supplied by M.A.C Solutions. The iX Panel T60 is a high performance HMI with a robust IP66 lightweight aluminium construction. The HMI has a 5.7-inch touchscreen colour display and includes Beijer’s iX runtime software. The 320 x 240 pixel display ensures excellent viewing in all conditions and a large viewing angle at all times.

The iX Panels is the next-generation in Beijer’s ‘award-winning’ EXTER series HMIs. The iX Panel series offers three keypad models and five touchscreen models to choose from.

On the industrial oven, AMP supplied two iX Panel T60 HMIs, which are now installed on each door of the oven, to control the locks and to ensure that no operators can enter the oven at certain times during the cooking process.

“The operators now use the HMI’s touchscreen display to control the complete oven cooking cycle. Once the oven is loaded, an operator uses the touchscreen display to set up the cooking cycle. An alarm can be set on the high-risk side of the oven, preventing any operators from entering through that door whilst cooking is in progress. Alarms can be both visual and audible. Once the cooking is completed, this information is again entered via the touchscreen,” explains Taylor.

“The primary benefit to the customer is eliminating the risk of contamination of the meat, however, the new HMIs have also helped to speed up the whole cooking process,” adds Taylor

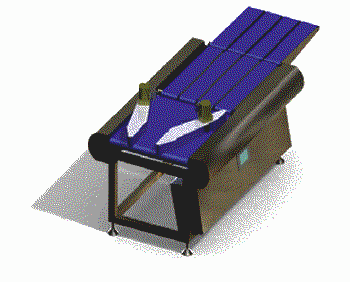

Servo-driven channeliser

AMP has also specified an iX Panel for a new development machine that the company is currently working on. As Taylor describes: “We purchased an iX Panel T40 HMI for this job, which involves the design and build of a servo-driven channeliser [conveyor] machine for food packs. Normally, the customer would use a pneumatic-driven machine, but our servo-driven machine offers a higher throughput, from 140 to 160 packs per minute.

“Although we haven’t quite finished testing the new machine yet, the iX Panel T40 will even allow me to upload a photo of the complete channeliser machine and to then set certain zones of the machine as selectable on the HMI display. The interface is intuitive and familiar to operators, which makes training faster and easier.”