A major industrial laundry in Bourg-en-Bresse, France, recently tested and installed the DataMan 300 reader from Cognex for reading barcodes on hangers and clothing

A major industrial laundry in Bourg-en-Bresse, France, recently tested and installed the DataMan 300 reader from Cognex for reading barcodes on hangers and clothing

Using the DataMan 300 reader the laundry, which processes 40 tonnes of laundry a day, including 18,000 pieces of clothing, has been able to reach a read rate of 99.99% observed, which results in reduced costs and increased speeds.

In this laundry, each piece of clothing and each hanger can be identified with a nominative label and unique barcode, constantly guaranteeing their traceability. Reading the codes is therefore essential for the operation of the laundry.

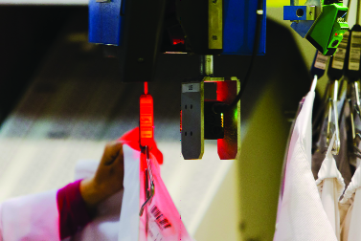

Reading codes is carried out in two specific zones – the sorting zone and the inspection zone. After washing, the pieces of clothing are placed on hangers and carried to the sorting zone, where they pass at a rate of one hanger code every 12cm – 120 pieces of clothing are processed per minute. Reading the barcode written on the hangers allows the clothing to be directed to the storage zone allocated to its owner before dispatching.

In the inspection zone, an operator inspects each piece of clothing and looks for holes, stains or other defects that would require additional treatment for the piece of clothing (repair or cleaning again). In this zone, the codes are located on both the clothing and the hanger. Reading them allows the piece of clothing to be located.

Jean-François Guillemin, the maintenance manager of the laundry explained, “Up until now we were using laser scanners for these reads, and it was difficult to achieve a read rate of 97% in the best cases. This represents an average of 500 unread hangers and as many pieces of non-allocated clothing that have to be sorted again manually. This results in wasting time and money.”

Jean-François Guillemin, the maintenance manager of the laundry explained, “Up until now we were using laser scanners for these reads, and it was difficult to achieve a read rate of 97% in the best cases. This represents an average of 500 unread hangers and as many pieces of non-allocated clothing that have to be sorted again manually. This results in wasting time and money.”

Time for change

The laundry in Bourg-en-Bresse was therefore trying to improve this reading on hangers. A Cognex image-based 1D and 2D DataMan 300 barcode reader, which is well suited to a laundry application, was installed and tested. The results were convincing right from the start and the laundry equipped its sorting and ‘inspection’ zones with these readers. In these two zones, the use of an imager instead of a laser scanner has allowed for more robust decoding.

Thanks to these patented technologies, DataMan 300 is well suited for the issues of an industrial laundry – benefiting from an IP65 seal, it can process a large number of barcodes, in good or not so good condition, with read rates of practically 100%, easy deployment and long service life for the system.

“The barcodes printed on clothing and on the hangers are permanent and are subjected to harsh conditions, between repetitive washings, impacts and multiple handling. Codes that are tarnished, scratched, worn – it doesn’t matter. DataMan 300, powered with the 1DMax+ software, is able to read all of the codes, even the most damaged ones, regardless of their position and their orientation,” emphasised Guillemin.

This is an advantage, especially in the inspection zone where the hangers swing a lot in front of the reader making reading difficult.

Additional benefits

DataMan 300 has other economic advantages – putting them into service in the laundry was simplified thanks to their autofocus and built-in LED lighting. The reader itself adjusts the light required for correct reading, with no human intervention. In addition, a single device is needed to read the two code sizes that correspond to the two types of hangers – so two DataMan 300s are enough to replace the three laser scanners that were installed on the inspection station. Another advantage is the possibility of viewing and transferring images from the reader, making it possible to analyse why codes are not read, when this occurs.

DataMan 300 has other economic advantages – putting them into service in the laundry was simplified thanks to their autofocus and built-in LED lighting. The reader itself adjusts the light required for correct reading, with no human intervention. In addition, a single device is needed to read the two code sizes that correspond to the two types of hangers – so two DataMan 300s are enough to replace the three laser scanners that were installed on the inspection station. Another advantage is the possibility of viewing and transferring images from the reader, making it possible to analyse why codes are not read, when this occurs.

Since the installation of the DataMan 300 readers in its sorting and inspection zones, the laundry has recorded impressive results – the successful read rate for codes increased from 97% to more than 99.9% observed. And the number of unallocated pieces of clothing dropped to under 50. “As the read is more reliable, sorting errors disappeared and delivering the right piece of clothing to the customer is now guaranteed, in all cases,” concluded Guillemin.

A video explaining the Bourg-en-Bresse laundry application can be view on www.connectingindustry.com/dataman.

Cognex

T: 01327 856 040