SolidCAM exhibited its InventorCAM 2014 software, which is a Certified Partner Product for Autodesk Inventor, on its booth at Autodesk University 2013 in Las Vegas in December.

SolidCAM exhibited its InventorCAM 2014 software, which is a Certified Partner Product for Autodesk Inventor, on its booth at Autodesk University 2013 in Las Vegas in December.

Autodesk University took a new turn in 2013, making a special feature of the latest in manufacturing software from SolidCAM and associated CNC machine technology, in a conference that had traditionally focused on design for mechanical, architecture, civil engineering and computer graphic animation.

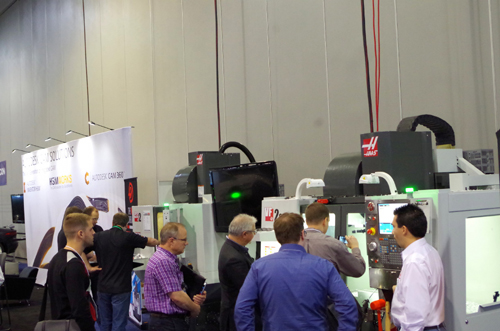

Huge screens on the InventorCAM booth displayed the latest advances in InventorCAM’s CNC Machining technology, including its iMachining and, coupled with the adjoining HAAS CNC machines, enabled hundreds of mechanical design oriented attendees to see the design to manufacture process in action.

Many commented on how interesting and exciting CAM technology is now and how they would be more open to in-house CNC machining production. Even those in other design areas voiced their interest in CAM as, for many, it was the first time Autodesk had prominently featured CAM and CNC machining.

Carl Bass, CEO of Autodesk, mentioned CAM several times in his keynote address and there were special breakout sessions focused on educating people on how they can turn their designs into reality using CNC machines.

Shaun Mymudes, COO of SolidCAM of North America commented, “AU 2013 was a successful show for us, with Autodesk promoting the subtractive CNC technology of CAM in addition to its traditional focus on 3D printing. The CAM pavilion was continuously active and people were eager to know more about InventorCAM, iMachining and CNC machining in general. Our ability to provide the full integrated CAM solution for Inventor, Inventor LT and AutoCAD, put us in a great position to really reach out to a new audience.”

InventorCAM’s CAM software, with modules for all CNC applications, includes the patented iMachining, and is seamlessly integrated in Autodesk Inventor. It has full toolpath associativity to the Inventor model, automatically synchronizing the toolpath to model changes.