Interroll has launched a new generation of drum motors that will be predominantly used for conveyor belt systems in distribution centres, production areas and in hygienic applications in the food industry.

Interroll has launched a new generation of drum motors that will be predominantly used for conveyor belt systems in distribution centres, production areas and in hygienic applications in the food industry.

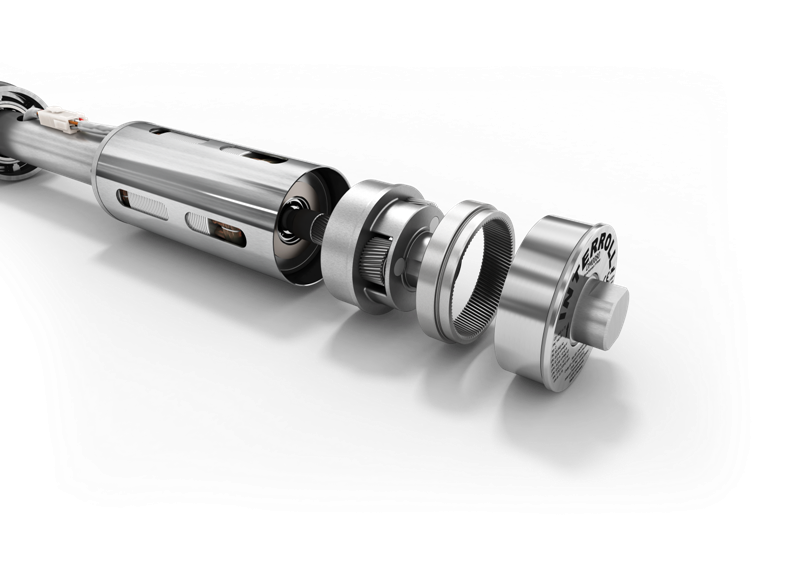

The motor platform is of modular design, encompassing both synchronous and asynchronous technologies. It is available first in 80mm-diameter drums and in future will be expanded to the entire product range.

The new platform makes it easy to combine all components and guarantees short and reliable delivery times. Options such as encoders, brakes and return stops, are available for all variants, making it easier for system integrators and equipment manufacturers to plan and implement efficient materials-handling solutions. The motors are IP69K protected.

Compared to Interroll’s previous generation, the new motors are distinguished by a series of design benefits. Stronger shafts and ball bearings guarantee a long service life, while robust planetary gears make it possible to transfer high levels of torque to conveyor belts efficiently and quietly. An expanded number of gear stages provides a greater speed range, making it easier for system integrators and equipment manufacturers to design conveyor systems that achieve their throughput requirements precisely.

The new platform’s modular design reduces production and delivery times. Unlike previous generations, there is an option for a simple plug-in connection, reducing downtime for maintenance and repair work, resulting in considerable cost advantages for the user.The drum motors also offer high energy efficiencies compared to alternative drive systems, cutting operating costs further.

01536 312770