As machine builders are required to produce more complex systems to accommodate their customers’ requirement for flexible manufacturing, Omron is able to offer products and support that can be integrated under one network; EtherNet/IP.

As machine builders are required to produce more complex systems to accommodate their customers’ requirement for flexible manufacturing, Omron is able to offer products and support that can be integrated under one network; EtherNet/IP.

Traditionally, the control system architecture of a machine is very complex, and is built up of a number of different networks connecting to a number of different devices.

These systems are constructed with a mixture of serial communications, fieldbus networks, and locally wired devices. Often using different wiring, they take a long time to set up, which can result in complicated commissioning and difficult troubleshooting. Therefore, a system is created where this commissioning cost is unknown and the benefits of intelligent devices are not passed on to the end user as the centralised information that should aid troubleshooting during the machines operation is lost. Having intelligent devices, such as safety controllers, inverters or temperature controllers, where diagnostics can only be seen locally to that device, restrict its capability, and reduce the overall intelligence of a machine.

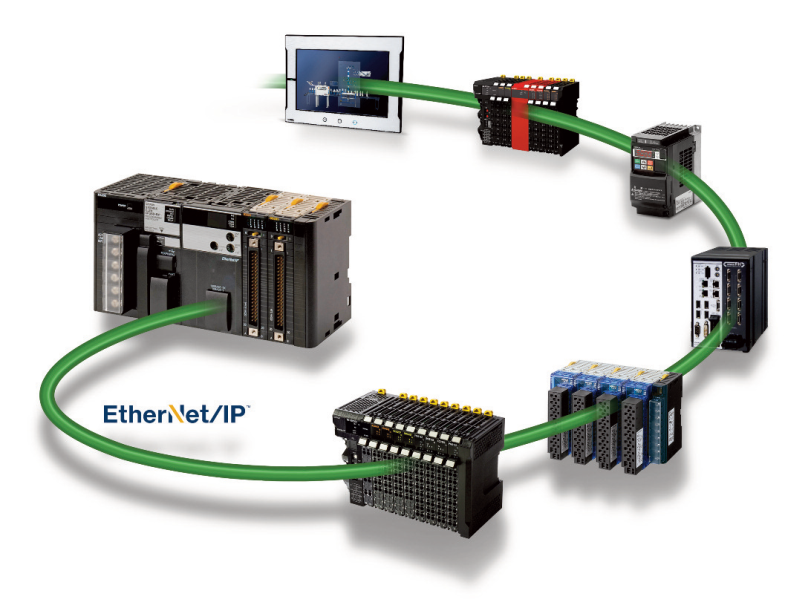

EtherNet/IP is an industrial protocol for intelligent devices, and uses standard off-the-shelf components for cabling and switches, but offers the robustness to support the communications required for an industrial machine or process. Utilising a single EtherNet/IP network for your control system architecture can offer the following benefits:

- Reduced set-up time as all the devices sit on one communications protocol, and use one type of cabling system.

- Reduced commissioning time as the complexities of multiple communication issues are removed.

- Troubleshooting is quicker and clearer, as errors and information can be centralised from intelligent devices back to an HMI.

With this system we can create the opportunity to build in preventative maintenance actions, which will increase the intelligence of a machine and in doing so reduce the overall cost to the user.

In addition, implementing one network throughout a machine, means that an HMI can now truly become the single point of machine interaction, as through the PLC controller, we can also connect to; remote I/O, Inverters, vision systems, temperature control, RFID, safety controllers and safety scanners all via EtherNet/IP. Omron’s clear advantage is in the ability to offer a wide range of EtherNet/IP products and support for one network, one solution from one supplier.

Omron Electronics