The Item Rack and Pinion drive system from Machine Building Systems is said to offer many advantages over conventional bolt-on designs.

The Item Rack and Pinion drive system from Machine Building Systems is said to offer many advantages over conventional bolt-on designs.

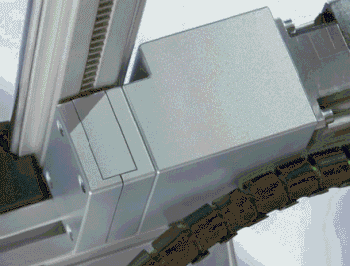

The rack is designed to sit entirely within the T-slot groove of any line 8 aluminium extrusion which allows compact linear slides to be constructed without a bolt-on driving mechanism. No part of the rack projects above the surface of the profile. The groove ensures that the rack is aligned parallel to the guide mechanism without unwanted snaking that is often experienced with alternative racks.

Racks of varying length can be built up using any number of individual rack segments. Manufacturing in 80mm pieces allows higher degrees of accuracy than longer lengths, where pitch errors can be significant, and reduces wastage where much longer racks would have to be cut down to suit the application.

Assembly couldn’t be simpler. An end section is secured in place with a single dowel screw, and a patented spring clip secures consecutive pieces without further machining. A second end section is secured in place with a dowel screw.

The matching 18-tooth pinion is mounted via double ball-bearings in a housing neatly secured to the underside of the moving carriage plate. A coupling module is attached to the pinion housing and the pinion’s keyed shaft engages with the coupling set contained within. The housing is adjusted to eliminate backlash before being fixed securely in position. The housing is machined according to requirements for the purpose of attaching the drive motor.

Maintenance only requires a few drops of light oil to the pinion housing containing a pair of felt discs for transferring the lubricant to the pinion. The drive system is designed for applications with a driving force of up to 1,000N, maximum motor torque of 23Nm and for speeds of up to 3m/s.