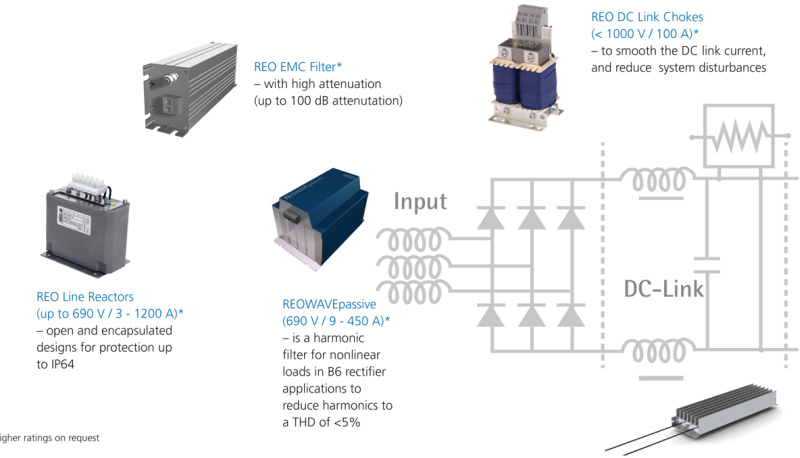

REO is taking the opportunity at the Drives and Controls exhibition to present its range of Drive peripheral components, known as REO Unity. This comprehensive range provides Drive manufacturers and integrators alike with a single source for EMC components, like RFI Filters and Input chokes, as well as performance enhancing products like output chokes and sinewave filters. In addition there is a comprehensive range of braking resistors.

REO is taking the opportunity at the Drives and Controls exhibition to present its range of Drive peripheral components, known as REO Unity. This comprehensive range provides Drive manufacturers and integrators alike with a single source for EMC components, like RFI Filters and Input chokes, as well as performance enhancing products like output chokes and sinewave filters. In addition there is a comprehensive range of braking resistors.

Unique to REO is the capability to present all components in high ingress protection versions, for example IP64, but also in force air-cooled and even water cooled versions.

REO provide application assistance to help customers select the correct part and even provide an EMC testing service for individual products to help customers satisfy compliance issues.

REO have a wide customer base in the drives sector, from HVAC to Drives used in renewable applications. They have a good understanding of what is required from a technical point of view but what specific applications demand too.

REO have a wide customer base in the drives sector, from HVAC to Drives used in renewable applications. They have a good understanding of what is required from a technical point of view but what specific applications demand too.

More and more Drive applications are utilising water as a cooling medium. In many instances the use of water allows drive enclosure sizes to be reduced and also allows higher ingress protection ratings for those challenging environments where protection of the Drive and the associated control gear is essential.

Of course, in many of these applications there are requirements for braking resistors, chokes and RFI filters and in the past the considerable losses presented by these components have compromised the efficiency and success of the system as a whole.

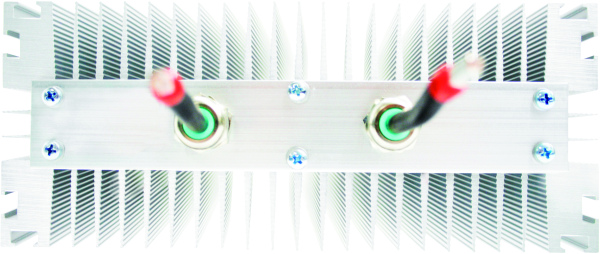

REO are now able to offer water cooling for all of its components, allowing up to 95% of the power losses in components such as input and output chokes and brake resistors to be transferred to the cooling medium, where it can be exchanged in a controlled manner or often be utilised in other aspects of the application, for example for carriage heating in railway traction applications.

REO are now able to offer water cooling for all of its components, allowing up to 95% of the power losses in components such as input and output chokes and brake resistors to be transferred to the cooling medium, where it can be exchanged in a controlled manner or often be utilised in other aspects of the application, for example for carriage heating in railway traction applications.

Water cooled components are up to 80% smaller than their air-cooled equivalents, this is important for automotive applications, but they also run considerably cooler, meaning that reliability and product life is greatly enhanced. As a safety measure, REO water cooled brake resistors are designed to run for 5 minutes at their rated power without any coolant to ensure the system can be safely shut down.

The REO water cooling system is not limited to the standard water/glycol mix, but can also be configured for use with oil or even sea water, this has proven essential in some marine applications.

One of our latest projects to provide braking capacity for a newly developed hybrid farm vehicle is perhaps the most interesting yet.

The vehicle utilises 4 x 33 kW motors to drive each wheel separately with active slip control on each. This combined with 4 wheel steering means that the unit combines great manoeuvrability with controlled torque to reduce soil and crop disruption.

The vehicle utilises 4 x 33 kW motors to drive each wheel separately with active slip control on each. This combined with 4 wheel steering means that the unit combines great manoeuvrability with controlled torque to reduce soil and crop disruption.

In addition to the usual functions associated with agricultural vehicles, the unit is able to supply connected equipment with a variety of AC or DC voltages up to a maximum power of 80 kW, to allow remote working in all but the most challenging weather conditions.

As with most electrical and hybrid vehicles, the braking is a combination of conventional friction brakes and regenerative braking, with a REO water cooled braking resistor to handle emergency conditions.

For this project not only did REO have to ensure that the water cooled resistor was able to dissipate the required electrical power but that the mechanical construction of the resistor was robust enough to withstand the environmental aspects of being mounted on a moving vehicle. Of course REO’s experience in dealing with similar components in the Automobile and Railway Traction industries meant that the requirements were easily met.

To make it easier to specify and purchase these components, REO has recently launched www.reopowersolutions.com an online shop bringing together these products in one place. As you would expect, the site offers next day delivery at competitive pricing for a number of products, but in addition it provides a useful knowledgebase of information concerning Drive installation issues, particularly relating to Drive EMC and EN61800-3.

REO’s knowledge of Drive applications is considerable, from simple HVAC applications to projects in the Electric Vehicle and Renewables sector and the FAQ section of the site provides a forum where REO are able to pass on this experience in bite-sized chunks to its customers.

At the moment, the site is offering components suitable for Drive power ratings up to 37kW, but there are plans to expand this in 2012 as customer requirements grow.