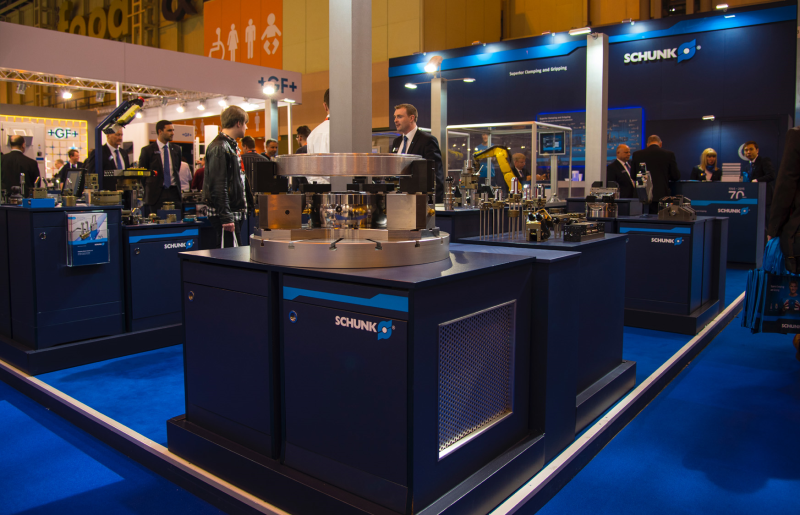

MACH 2016 was all about ‘Synergy’ for Schunk. The workholding, toolholding and automation specialist had its equipment on at least nine other exhibitor stands at the UK’s showpiece manufacturing event – a glowing endorsement for the industry leading brand. With Schunk’s world leading equipment in operation on the stands of DMG Mori, Fanuc, ETG, Citizen and ABB Robotics to name a few, Schunk was clearly the first choice automation specialist and workholding partner for exhibitors and MACH visitors alike.

MACH 2016 was all about ‘Synergy’ for Schunk. The workholding, toolholding and automation specialist had its equipment on at least nine other exhibitor stands at the UK’s showpiece manufacturing event – a glowing endorsement for the industry leading brand. With Schunk’s world leading equipment in operation on the stands of DMG Mori, Fanuc, ETG, Citizen and ABB Robotics to name a few, Schunk was clearly the first choice automation specialist and workholding partner for exhibitors and MACH visitors alike.

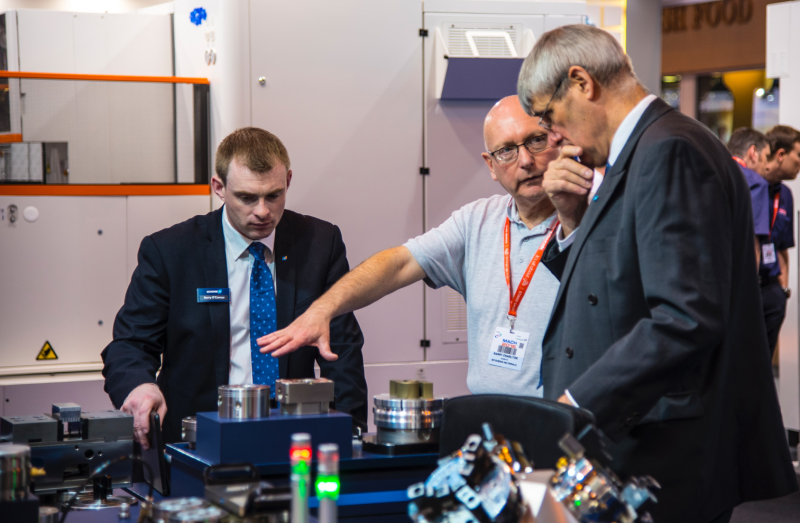

With an exhibition stand more than double the size of previous events, MACH proved the ideal platform for announcing new product launches, a new web portal and also new area sales managers. On top of all this, Schunk had industry expert’s on-hand to discuss Schunk’s latest product innovations that meets the criteria of Industry 4.0. The culmination of all these factors has brought the Schunk sales team a record number of sales leads and enquiries from exhibition visitors.

At the centre of customer interest with regard to Industry 4.0 was Schunk’s innovative new eGrip system. Acknowledged as the world’s first fully-automated design and ordering tool for additive manufactured gripper fingers, the SCHUNK eGrip is a browser-based, license-free application to create and order tailor-made gripper fingers in just a few mouse clicks. Users just have to upload STEP or STL data of the part to grip, and add specific information such as weight, gripper base, mounting direction and relative position of the part to the gripper. The software automatically configures the gripper fingers around the part, generating the optimal finger design, and immediately gives price and estimated delivery information. With nothing remotely close to this level of technology on the market, Schunk certainly impressed automation customers at MACH.

For machine shops and manufacturers attending MACH, Schunk drew customers’ attention to the latest interfaces available for the Schunk TRIBOS system. Developed to improve surface finishes and tool service lives, the innovative TRIBOS system and its new interfaces will deliver a higher level of standardisation for precision tool holding. Some of these micro machining interfaces are now available with the TRIBOS RM and TRIBOS MINI ranges.

For machine shops and manufacturers attending MACH, Schunk drew customers’ attention to the latest interfaces available for the Schunk TRIBOS system. Developed to improve surface finishes and tool service lives, the innovative TRIBOS system and its new interfaces will deliver a higher level of standardisation for precision tool holding. Some of these micro machining interfaces are now available with the TRIBOS RM and TRIBOS MINI ranges.

Additionally, Schunk emphasised the benefits of its TENDO E Compact hydraulic expansion toolholder at MACH 2016. Capable of reducing set-up times by up to 60% whilst generating 2000Nm of torque, the TENDO E Compact delivers micron precision for a host of machining applications. With this precision toolholder, even demanding applications with tight tolerances on the form, position and surface finish can be rapidly and reliably machined.

Alongside these products was the market leading MAGNOS range of magnetic chucks. Taking the renowned MAGNOS to a new level, Schunk has equipped the MAGNOS with a permanent display that informs the operator on the clamping status of the magnetic chuck. At MACH, customers could see at a glance whether the MAGNOS is activated or not.

The magnetic chuck is fixed to the machine table and then connected via a sealed quick release connector to the control unit. As soon as it is activated, the light of the permanent status display turns to green. The display works independently from the power supply and will also be visible if the power cable has been disconnected after activation of the permanent magnet. With the MAGNOS square pole plates, workpieces can be quickly clamped and are machined in one set-up from five sides, ideal for 5-axis machining. For anybody that couldn’t make it to MACH 2016, you can get further details on the extensive Schunk product range from your local Schunk representative or by browsing the new website.