PC software suite for robotics application development and maintenance

PC software suite for robotics application development and maintenance

Stäubli, a leading manufacturer of industrial robots, has announced the release of their new Stäubli Robotics Suite version 2013. Stäubli Robotics Suite is an integrated Development, Simulation and Maintenance environment running on a Windows® platform, which facilitates the development of robotic applications. It is the ideal companion to the various methods of programming a Stäubli robot, VAL 3 – the interpreted programming language particularly well-suited for integrators and OEMs, VALproduct solutions – ready to use industry solutions adapted for end users and uniVAL drive – a “ready to plug” solution to drive Stäubli robots with generic industrial motion controllers, perfectly adapted for machine builders.

The innovative Stäubli Robotics Suite features a new single window presentation with ribbons similar to those seen in recent Windows updates, making it very intuitive yet powerful to use, with all functions readily accessible. Stäubli Robotics Suite version 2013 includes two integrated modules, Development Studio and Maintenance Studio.

The innovative Stäubli Robotics Suite features a new single window presentation with ribbons similar to those seen in recent Windows updates, making it very intuitive yet powerful to use, with all functions readily accessible. Stäubli Robotics Suite version 2013 includes two integrated modules, Development Studio and Maintenance Studio.

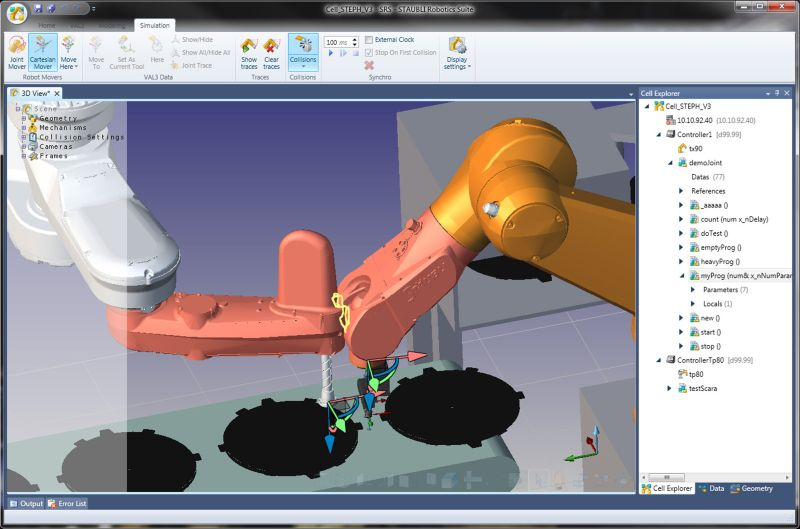

Development Studio is a software workbench for robotics application development and 3D simulation. Built-in functions include file transfer between the development PC and the robot controller, automatic or manual backups, visualization of robot arms in a 3D environment as well as execution or modification of VAL 3 programs. In addition, it features a powerful VAL 3 program editor, bringing high-end functionalities such as 3D visualization into programming tools, online debugging, auto-completion and intelli-sense functions. CAD data can be imported in various formats (STEP, IGES, STL, VRML). Models can also be built using standard primitives (cubes, spheres, etc…). The program editor is directly linked to the 3D environment for geometric data creation and editing. Full multi-robot simulation is possible, providing realistic cycle times through the individual clocking of each robot controller in the cell in a real-time fashion. High performance collision detection is also included in the package with highlighting of the colliding objects and minimum distance verification. These new features are designed to save precious time during application development.

Maintenance Studio is designed for maintenance personnel and provides advanced functionalities to perform diagnostic operations. It features full remote access to the controller with 3D visualization of the robot system. The robot can be controlled from a remote PC with live visual feedback of any operation performed on the teach pendant by the operator. A 3D environment is available in visualization mode, with the ability to load a 3D robot cell previously created in Development Studio.

To meet the growing needs of businesses with increasingly advanced robotic solutions, Stäubli Robotics is committed to continued development of software products that perform and are easy to use.

For additional information, please contact:

Stäubli (UK) Limited

Paul Ralphs – Technical Sales and Support Engineer – Robotics Division

Phone: +44 (0)1952 671917 Fax: +44 (0)1952 608579 Email: robot.uk@staubli.com

About Stäubli: Textile Machinery, Connectors and Robotics

Stäubli is a mechatronics solution provider with three dedicated divisions: textile machinery, connectors and robotics. With a workforce of 4000, Stäubli has a presence in 25 countries and agents in 50 countries around the world.