Tobacco industry machine supplier and refurbisher, Hampshire Tobacco Machinery Services is conquering modern safety legislation more easily thanks to advanced hardware and software from Rockwell Automation

Tobacco industry machine supplier and refurbisher, Hampshire Tobacco Machinery Services is conquering modern safety legislation more easily thanks to advanced hardware and software from Rockwell Automation

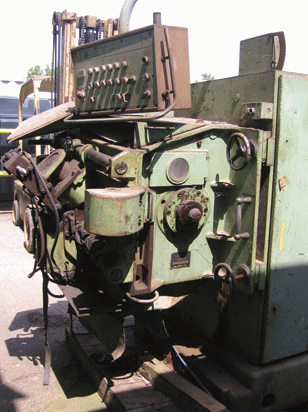

Hampshire Tobacco Machinery Services (HTMS) was established in 1986, initially for the supply and manufacture of machine spare parts and re-engineered secondary machinery (cigarette manufacture and packaging) – as both individual machines or as complete maker/packer combinations – together with an after sales service for spare parts. Today, the company’s principal interest is the supply of new packing equipment, centred on hard box, hinge lid packing machinery.

Although there are many companies engaged in this field worldwide – many who are larger than HTMS – the company’s managing director can uniquely claim to have been at the vanguard of those introducing the concept of re-engineering to the industry. The company assists a number of UK and European production manufacturers to develop existing machinery, raising its efficiency and converting size in accordance with market trends.

One of the primary challenges that HTMS faces, alongside the introduction of modern control systems, is bringing older machines up to modern standards, especially with regards to international machinery safety directives.

One of the primary challenges that HTMS faces, alongside the introduction of modern control systems, is bringing older machines up to modern standards, especially with regards to international machinery safety directives.

The machines it re-engineers – some of which were built in the 1940s – often do not have any form of contemporary safety functions; and certainly not those that concur with modern directives such as EN ISO 13849-1. So HTMS really has a challenge when it comes to bringing older machines up to required specification.

As well as incorporating an approved safety infrastructure into these older machines, HTMS faces another major issue, in common with the vast majority of machine builders, and that is certifying the machines to the standards laid down by EN ISO 13849-1. It’s for this reason that HTMS called upon the services of Rockwell Automation; not only for its comprehensive range of safety solutions, but also for its knowledge, help and tools that would help HTMS address the demands of these standards.

The integration of safety and machine control is now a common request to Rockwell Automation. Having safety and automation closely interlinked generates a huge range of benefits including: reduced wiring; common, single-platform training and programming; fewer ‘between-systems’ data bottlenecks; and reduced overall cost.

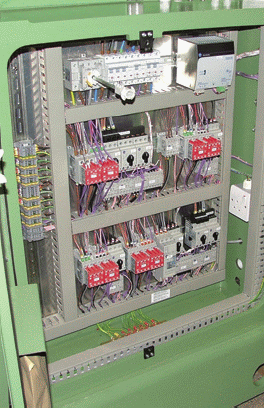

It was for these reasons, among others – on a machine it was refurbishing that was built in the 1980s – that HTMS opted for a control and safety solution based on an Allen-Bradley MicroLogix 1200 PAC connected with an Allen-Bradley SmartGuard 600 programmable safety controller.

The idea was to automate the machine while certifying the safety system using the new EN ISO 13849-1 Functional Safety Standards. HTMS and Rockwell Automation jointly assessed the machine, developed the solution and designed and engineered a state-of-the-art safety solution.

Bringing the machine up to modern standards, other components from the extensive safety range from Rockwell Automation included software, connectors, RSNetWorx, SensaGuard RFID coded safety interlock switches, 100S Safety Contactors and Softstarts. Finally – and one of the most beneficial facets of this project – was HTMS’s use of SISTEMA software to evaluate the machine’s safety in relation to EN ISO 13849-1.

Commenting on the equipment and, in particular, the use of the SISTEMA software, Pete Woodthorpe, Technical Director at HTMS, explains: “The approach to evaluating the safety of the system is very similar to the way we used to do it. By using SISTEMA we are able to assess the machine by areas or modules, unlike the old way where you looked at the machine as a whole. Everything is so much simpler and the process is made much easier by the fact that all of the Rockwell Automation equipment is in the SISTEMA library; so it is just a case of dragging and dropping the components into the application. You can almost immediately see if there are any safety issues. Not only is this far easier for us, it is also a whole lot easier for the user.

Commenting on the equipment and, in particular, the use of the SISTEMA software, Pete Woodthorpe, Technical Director at HTMS, explains: “The approach to evaluating the safety of the system is very similar to the way we used to do it. By using SISTEMA we are able to assess the machine by areas or modules, unlike the old way where you looked at the machine as a whole. Everything is so much simpler and the process is made much easier by the fact that all of the Rockwell Automation equipment is in the SISTEMA library; so it is just a case of dragging and dropping the components into the application. You can almost immediately see if there are any safety issues. Not only is this far easier for us, it is also a whole lot easier for the user.

“The engineers at Rockwell Automation have been invaluable with their advice and support, offering us help from day one with specialist support, equipment and programming. It has been a very smooth ride and has made our job significantly easier,” Woodthorpe concludes.

Thanks to the flexibility of the components supplied by Rockwell Automation, coupled with their interoperability and their presence within the SISTEMA library, the addition of contemporary safety solutions, even onto machines that are 70 years old, is now much easier and far less onerous than it used to be.