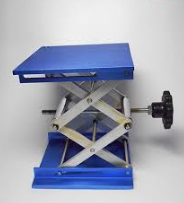

Manual lift tables are common equipment in numerous manufacturing industries. Their impact in industries has been enormous, and their applications extend to more than load lifting.

Manual lift tables are common equipment in numerous manufacturing industries. Their impact in industries has been enormous, and their applications extend to more than load lifting.

Some of the features that have made this table great include its portability, durability, and load capacity. The table not only works in the warehouse industry but also manufacturing, shipping, and even transport.

Its benefits to manufacturing ranges from saving production time, to cutting down costs, and improving productivity. It’s, therefore, a valuable tool for manufacturers.

The past few years have seen a rise in the applications of this table in industries. This has made it a far more popular device to opt for when automating.

Below, we look at five applications of this table to manufacturing industries.

Lifting and Lowering products

Every manufacturing industry has a warehouse, where they store their raw materials and finished products. To save on space, most warehouses use shelves and other high-reaching platforms to store these products.

Therefore, when you need to access materials at the top of the stack, using a ladder may not be the best option. You need an equipment that’s more stable and reliable.

That’s a manual lift table.

These tables raise and lower workers and goods to the desired heights safely and with ease. Industries use these tables mainly because they save time.

Moreover, their design makes it steadier, hence limiting the chances of industrial accidents.

Transporting goods

In any manufacturing workspace, there’s so much activity going on. Workers are continually moving to different stations, raw materials are transported in, and finished products out.

A lot of time is thus, wasted during these movements.

Manufacturers have thus devised a better way of transporting products and material quickly and more efficiently; Using the manual lift table.

The manual lift table is portableand can handle load capacities of different weights. This makes it easier to transport goods from one point of the industry to the other.

Moreover, depending on the size of your lift table, you can even move workers!

Loading and unloading

Statistics show that most employee injuries occurring in manufacturing industries occur during the loading and unloading process. As such, managers are continually looking for better ways to improve this situation.

Luckily, the manual lift table has become a good solution for this problem.

Regardless of the weights of your products or raw materials, the lift table can quickly loadthe items for production. It can also equally unload the items after production.

This is made possible by the fact that manual lift tables come in numerous sizes and capacities. Some manual tables are designed to handle lighter loads, while others level heavier ones.

There also exist customized manual lift tables, specifically designed to suit your business. Therefore, your employees don’t have to strain to do heavy tasks.

Inspections

When it comes to safety in your manufacturing industry, you can never be too sure. There’s just so much that could go wrong in a jiffy.

That’s why you need to be very cautious with your inspections. Not only product inspections, but also the state of your workplace. You can’t avoid looking into those high areas, the ceilings, pipes, and other devices that may not be in the best shape.

Manual lift tables come in handy during such tasks due to their flexibility and portability.

They are used to lift inspectors to higher levels, allowing them to come up with comprehensive reports.

The table allows you to detect and determine faults such as leaking gas pipes on time, and have it fixed before it’s too late.

Conclusion

The above applications are but a few of the many ways the manual lift tableis helping out in industries. Its also applied in other fields like the medical industry when stocking drugs in the pharmacy and to transport test samples to the lab.

However, the manufacturing industry is one that has embraced this equipment fully, and so far, its impact has been incredible.

Therefore, before looking for a better equipment for your industry, be sure to check out the manual lift table.

Manual lift tables are common equipment in numerous manufacturing industries. Their impact in industries has been enormous, and their applications extend to more than load lifting.

Some of the features that have made this table great include its portability, durability, and load capacity. The table not only works in the warehouse industry but also manufacturing, shipping, and even transport.

Its benefits to manufacturing ranges from saving production time, to cutting down costs, and improving productivity. It’s, therefore, a valuable tool for manufacturers.

The past few years have seen a rise in the applications of this table in industries. This has made it a far more popular device to opt for when automating.

Below, we look at five applications of this table to manufacturing industries.

- Lifting and Lowering products

Every manufacturing industry has a warehouse, where they store their raw materials and finished products. To save on space, most warehouses use shelves and other high-reaching platforms to store these products.

Therefore, when you need to access materials at the top of the stack, using a ladder may not be the best option. You need an equipment that’s more stable and reliable.

That’s a manual lift table.

These tables raise and lower workers and goods to the desired heights safely and with ease. Industries use these tables mainly because they save time.

Moreover, their design makes it steadier, hence limiting the chances of industrial accidents.

- Transporting goods

In any manufacturing workspace, there’s so much activity going on. Workers are continually moving to different stations, raw materials are transported in, and finished products out.

A lot of time is thus, wasted during these movements.

Manufacturers have thus devised a better way of transporting products and material quickly and more efficiently; Using the manual lift table.

The manual lift table is portableand can handle load capacities of different weights. This makes it easier to transport goods from one point of the industry to the other.

Moreover, depending on the size of your lift table, you can even move workers!

- Loading and unloading

Statistics show that most employee injuries occurring in manufacturing industries occur during the loading and unloading process. As such, managers are continually looking for better ways to improve this situation.

Luckily, the manual lift table has become a good solution for this problem.

Regardless of the weights of your products or raw materials, the lift table can quickly loadthe items for production. It can also equally unload the items after production.

This is made possible by the fact that manual lift tables come in numerous sizes and capacities. Some manual tables are designed to handle lighter loads, while others level heavier ones.

There also exist customized manual lift tables, specifically designed to suit your business. Therefore, your employees don’t have to strain to do heavy tasks.

- Inspections

When it comes to safety in your manufacturing industry, you can never be too sure. There’s just so much that could go wrong in a jiffy.

That’s why you need to be very cautious with your inspections. Not only product inspections, but also the state of your workplace. You can’t avoid looking into those high areas, the ceilings, pipes, and other devices that may not be in the best shape.

Manual lift tables come in handy during such tasks due to their flexibility and portability.

They are used to lift inspectors to higher levels, allowing them to come up with comprehensive reports.

The table allows you to detect and determine faults such as leaking gas pipes on time, and have it fixed before it’s too late.

Conclusion

The above applications are but a few of the many ways the manual lift tableis helping out in industries. Its also applied in other fields like the medical industry when stocking drugs in the pharmacy and to transport test samples to the lab.

However, the manufacturing industry is one that has embraced this equipment fully, and so far, its impact has been incredible.

Therefore, before looking for a better equipment for your industry, be sure to check out the manual lift table.