Automation consultancy GB Innomech (Innomech) has designed and developed a new semi-automated workstation to help a major UK-based manufacturer to improve the manufacturing efficiency for one of its leading ranges of high precision industrial sensors.

The new system will allow Michell Instruments to shorten production timescales, further improve product quality, and to increase its capacity to meet fast-growing international demand for its Easidew dew point sensors, particularly from the US and major European markets. Easidew sensors are routinely used for moisture measurement in gases and liquids across a broad range of sectors including industrial processing, medical gases, and compressed natural gas fuelling stations.

The new system will allow Michell Instruments to shorten production timescales, further improve product quality, and to increase its capacity to meet fast-growing international demand for its Easidew dew point sensors, particularly from the US and major European markets. Easidew sensors are routinely used for moisture measurement in gases and liquids across a broad range of sectors including industrial processing, medical gases, and compressed natural gas fuelling stations.

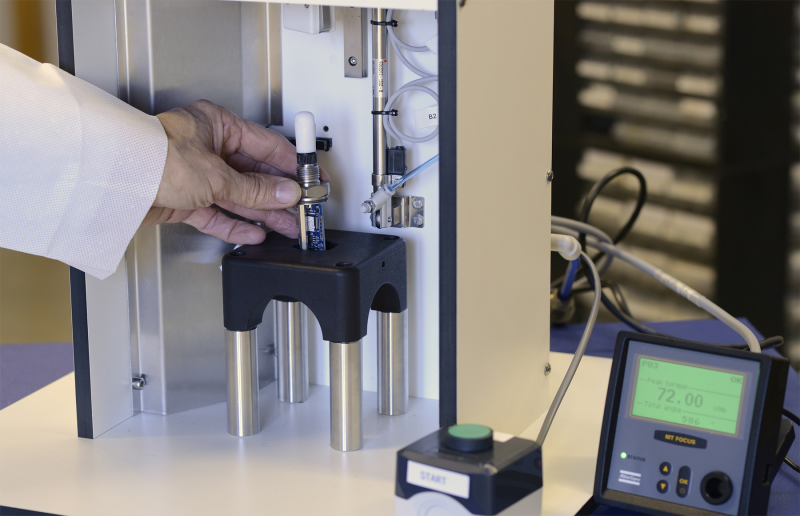

Innomech has designed the easy-to-use workstation to replace a previously repetitive and time-consuming manual task of screwing a polymer or stainless steel guard component onto the body of a sensor housing. The new system requires almost no operator training and is based on an Atlas Copco torque driver which tightens the two components together following a defined torque profile. The system can immediately identify and warn its operator of any cross-threaded components or if the guard is incorrectly seated at the end of the cycle.

Read more…

A full version of this story has been published in the March issue of Automation magazine which can be read online via this link.