In many manufacturing processes, temperature is the most critical physical measurement necessary to ensure production integrity and product quality. Non-contact infrared pyrometers provide an ideal solution for fast and reliable monitoring, analysis and control of process and product temperatures. They allow users to ensure high quality standards in conformance with DIN EN ISO 9001 requirements on production lines.

In many manufacturing processes, temperature is the most critical physical measurement necessary to ensure production integrity and product quality. Non-contact infrared pyrometers provide an ideal solution for fast and reliable monitoring, analysis and control of process and product temperatures. They allow users to ensure high quality standards in conformance with DIN EN ISO 9001 requirements on production lines.

Raytek, a specialist in infrared temperature measurement, has developed a compact and high-performance sensor solution especially designed for applications requiring flexible and highly-accurate temperature monitoring in small or limited spaces.

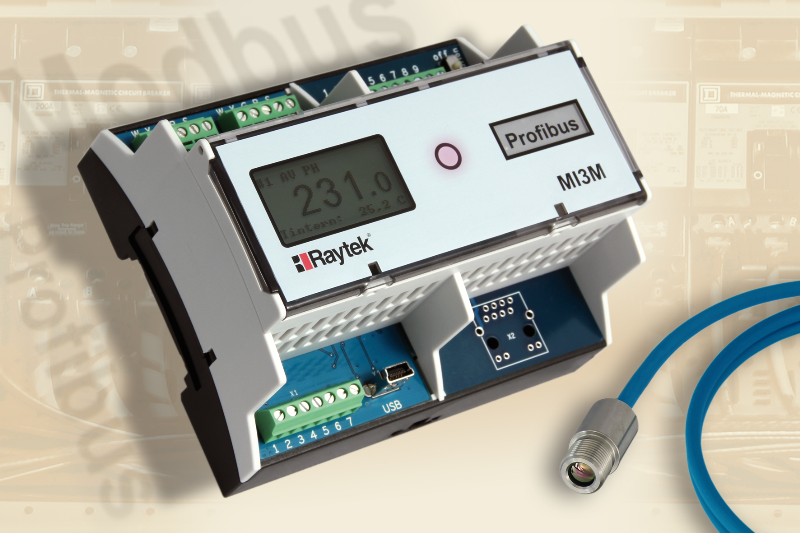

The self-contained temperature sensors featured in the Raytek MI3 Series of compact, non-contact infrared pyrometers are the smallest in the world with a length of only 28 mm and a diameter of only 14 mm. These extremely fast miniature sensor heads are contained in an IP65 stainless steel housing, and are connected to a separate communications electronics box, which is enclosed in protective or DIN-rail housing. Three different MI3 Series models monitor a broad temperature range from -40 to +1650 °C and are available optionally with an RS485 interface and Modbus or PROFIBUS connection respectively. This broad temperature range and high data accuracy make the MI3 Series ideal for use in a wide variety of manufacturing applications, especially for process monitoring.

Unique on the market, MI3 Series pyrometers automatically collect and convert the temperature measurement data into a digital signal directly in the sensor head. Functions, such as self-monitoring of cable breaks, greatly increase data reliability. An OEM version is also available in the MI3 Series, which enables the sensor head to be connected directly via the internal digital Bus for transmission of temperature data directly to existing automatic control systems without the need for the standard communications box. An additional unique feature of the MI3 Series is its multiple measurement head design: Up to eight individual addressable sensor measurement heads can be connected to the communications box – this greatly minimises installation complexity and cost. Setup and operation are extremely user-friendly. The digital communication between sensor heads and the communications box and patented automatic sensor head recognition enable initial plug-and-play operation without complex settings required. The robust MI3 sensors provide excellent EMV characteristics for reliable use in ambient temperatures of up to 120 °C without the need for additional cooling. Raytek DataTemp MultiDrop software is included with the communications box to allow unrestricted remote access to all temperature data from the sensor heads. For diagnostic purposes, users can also login locally via the standard USB interface.

Unique on the market, MI3 Series pyrometers automatically collect and convert the temperature measurement data into a digital signal directly in the sensor head. Functions, such as self-monitoring of cable breaks, greatly increase data reliability. An OEM version is also available in the MI3 Series, which enables the sensor head to be connected directly via the internal digital Bus for transmission of temperature data directly to existing automatic control systems without the need for the standard communications box. An additional unique feature of the MI3 Series is its multiple measurement head design: Up to eight individual addressable sensor measurement heads can be connected to the communications box – this greatly minimises installation complexity and cost. Setup and operation are extremely user-friendly. The digital communication between sensor heads and the communications box and patented automatic sensor head recognition enable initial plug-and-play operation without complex settings required. The robust MI3 sensors provide excellent EMV characteristics for reliable use in ambient temperatures of up to 120 °C without the need for additional cooling. Raytek DataTemp MultiDrop software is included with the communications box to allow unrestricted remote access to all temperature data from the sensor heads. For diagnostic purposes, users can also login locally via the standard USB interface.

MI3 sensor heads are well-suited for industrial applications, especially in those applications in which the previous use of otherwise bulkier non-contact temperature measurement sensors was not possible due to space limitations along the production path. Since only one communications box is required for up to eight measurement sensors, the setup and cost of multiple single-point temperature measurement using MI3 sensors is more flexible and economical than with other sensors of this kind currently available on the market.

MI3 Pyrometer Series Expanded with High-Temperature Models

MI3 Pyrometer Series Expanded with High-Temperature Models

For especially demanding applications, Raytek has recently expanded its M13 series of non-contact temperature measurement with two short-wave spectral sensors. The new 1M/2M temperature sensors are especially designed to measure reflective surfaces more accurately than previously available infrared sensors. They also cover an exceedingly broad and high measurement range: The 1M model measures a temperature range from 500 – 1800 °C (at 1 µm); the 2M model measures a temperature range 250 – 1.400 °C (at 1,6 µm). This allows single-point measurements to be set up flexibly and economically, depending on specific temperature ranges and surface types to be measured along a production path. The new short-wave sensors offer many of the same advantages of the existing MI3 product line, including high data reliability, ease of use and plug-and-play operation. In addition, the short-wave sensors are standardly equipped with laser sighting for accurate measurement target positioning. They deliver a very good resolution of 100:1 and are exceedingly fast with a response time of only 10 ms. In addition to plastic processing applications, the new 1M/2M temperature measurement heads also suitable for other industrial applications, such as the growing of solar silicon crystals used in solar power equipment, secondary metal treatment and processing, as well as in the manufacture of ovens and heaters.