Digital transformation and automation are the key issues today in all areas of industry. Cutting-edge ideas are therefore in demand in the development of modern manufacturing systems, as these ideas allow manufacturers to optimise their opportunities with regard to industry 4.0.

As a partner in industrial connectivity, we continue to promote intelligent networking within production. At the SPS IPC Drives, Weidmuller will demonstrate how they are shaping the future with innovative products and solutions and how they can enhance added value with cutting-edge networking solutions.

You can find detailed information about Weidmuller‘s displays at this year’s SPS IPC Drives 2018 as well as a free entry pass at: www.weidmueller.com/sps. Featured solutions will include:

u-mation

More than Automation. Digital Solutions.

Weidmuller‘s carefully constructed portfolio combines modular automation hardware as well as innovative engineering and visualisation tools with well thought out digitalisation solutions. Thus it enables the intelligent connection of all process levels – from the sensor to the cloud. Flexible u-control, the modular u-remote I/O system and the intuitive multi-touch panel provide access to a comprehensive hardware portfolio that offers maximum ?exibility for con?guring individual solutions. Weidmuller will present open, web-based and secure control software for the automation of small and medium-sized systems in the form of u-create

Industrial Analytics

Outpacing faults

Weidmüller‘s Industrial Analytics is a solution for data analysis used by customers in the machinery and plant engineering sectors to expedite the structural changes driven by digitalisation, and in particular to secure and expand their service business. Industrial Analytics is a software solution that enables machine and system operators to identify and predict anomalies and faults at an early stage in order to avoid outages and additional maintenance work, with a strong focus on machine learning and arti?cial intelligence. In this way, Weidmüller helps customers to achieve digital innovations themselves and to implement new business models.

Weidmüller‘s Industrial Analytics is a solution for data analysis used by customers in the machinery and plant engineering sectors to expedite the structural changes driven by digitalisation, and in particular to secure and expand their service business. Industrial Analytics is a software solution that enables machine and system operators to identify and predict anomalies and faults at an early stage in order to avoid outages and additional maintenance work, with a strong focus on machine learning and arti?cial intelligence. In this way, Weidmüller helps customers to achieve digital innovations themselves and to implement new business models.

Automation and digitalisation in practice

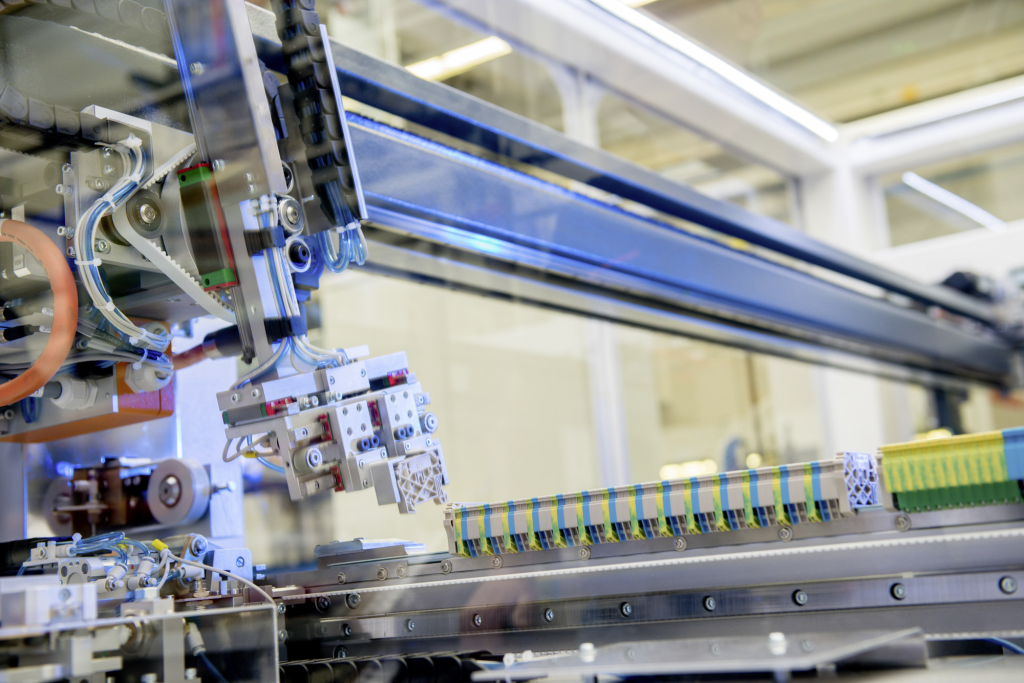

Automated panel building

Engineering processes need to be completed with ever-increasing speed, precision and ef?ciency. With the Weidmüller Con?gurator (WMC), Weidmüller has a powerful software solution that speeds up the selection, con?guration and ordering of products and solutions. Following con?guration of the terminal blocks or assembled enclosures, the Con?gure-to-Order tool provides a quick automated service and guaranteed delivery from four days after ordering, based on users‘ speci?c requirements. The digital models are transferred directly to their automated terminal rail assembly, without any intermediate manual steps. At the show, the Weidmuller team will be demonstrating the networking of automation and digitalisation on the Weidmuller stand by means of a live application focusing on the example of intralogistics.

Engineering processes need to be completed with ever-increasing speed, precision and ef?ciency. With the Weidmüller Con?gurator (WMC), Weidmüller has a powerful software solution that speeds up the selection, con?guration and ordering of products and solutions. Following con?guration of the terminal blocks or assembled enclosures, the Con?gure-to-Order tool provides a quick automated service and guaranteed delivery from four days after ordering, based on users‘ speci?c requirements. The digital models are transferred directly to their automated terminal rail assembly, without any intermediate manual steps. At the show, the Weidmuller team will be demonstrating the networking of automation and digitalisation on the Weidmuller stand by means of a live application focusing on the example of intralogistics.

Presentations: Weidmuller will be presenting on the following topics:

27 November, 5:20 pm: IoT modular kits – what does the solution for brown?eld and green?eld machines look like? Forum (Halle 10.1)

28 November, 10:40 am: Automated Machine Learning – (AutoML) needs domain expertise

Forum (Halle 10.1)

Weidmuller GTI Software GmBH Stand

Weidmuller GTI Software GmBH Stand

You can also discover even more solutions for machine control and machine visualisation at the Weidmüller GTI Software GmbH stand in Hall 7 – Stand 7-160.