The most innovative machine vision project winner at the PPMA Industry Awards

The most innovative machine vision project winner at the PPMA Industry Awards

Vision provides competitive advantage for Pharmaceutical supplier.

Machine Vision Technology (MVT), long term customers of Multipix, were approached by Pharma Packaging Systems Ltd (PPS) based in Pershore, Worcestershire. PPS are a company that specialise in packaging systems for the pharmaceutical industry. Primary business is design and manufacturer of counting systems for tablets and capsules. PPS identified an opportunity to offer their customers the benefits of Machine Vision by creating an inspection solution for their existing range of counting and bottling machines.

The purpose of the inspection is to check for broken, partially formed or cross contamination (rouge tablets that belong in a different batch). In the pharmaceutical industry, cross contamination, if left undetected before it leaves the manufacturer can cause the whole factory to be shut down for a period in addition to crippling fines.

Key advantages of the PPS online inspection system

- Verify it is the correct tablet so avoiding cross-contamination

- Measure length, width, area, completeness

- Verify colour

- Ensure quality

- Avoid product returns and the possibility of substantial fines/losses

- 80 images per second across 24 lanes of continuous tablet flow

PPS ideally wanted to work with a local company that also had the experience and capability of developing such a specialised system. MVT had previously developed a system for Schwartz Pharmaceutical, USA to inspect tablets so the cooperation was formed.

Challenges to overcome

In general terms the bulk product (tablets or capsules) feed from a hopper onto a cascade of grooved vibrating trays that separates the product and guides it along lanes in the stainless steel tray.

In general terms the bulk product (tablets or capsules) feed from a hopper onto a cascade of grooved vibrating trays that separates the product and guides it along lanes in the stainless steel tray.

As the tablets leave the end of the feed trays they pass through high speed infrared optical sensors that count the products in free fall. The products are counted with high accuracy, at high speed, into bottles that are indexed on a conveyor by a scroll drive system.

The innovation has been to place cameras above the final tray just before the tablets are counted and bottled. The tablets are vibrating, often touching and often bouncing down the trays which mean they can be presented to the camera in any possible orientation.

Another challenge to overcome was the shiny nature of the stainless steel trays and the reflections of the tablets in the sides of each channel of the tray. This presented real problems to the Vision system which needs to differentiate between actual and reflected products.

Innovative tablet tracking and multiple inspections ensure robust results

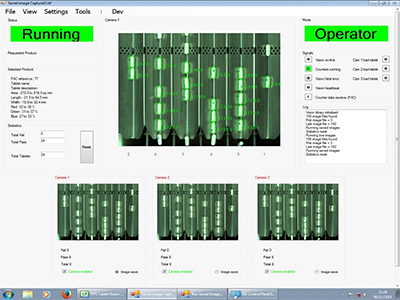

Each camera, positioned above the tray, images 6 lanes of tablets. Each tablet is typically inspected ten or more times as it passes from top to bottom through the camera’s Field Of View (FOV). The main problem to overcome was the product appearing to be either good or bad at any one instant in time depending on which face it was presenting to the camera as feeds down the tray. MVT spent over one year developing some very sophisticated tablet tracking software that tracks each individual tablet.

Each camera, positioned above the tray, images 6 lanes of tablets. Each tablet is typically inspected ten or more times as it passes from top to bottom through the camera’s Field Of View (FOV). The main problem to overcome was the product appearing to be either good or bad at any one instant in time depending on which face it was presenting to the camera as feeds down the tray. MVT spent over one year developing some very sophisticated tablet tracking software that tracks each individual tablet.

Once the inspection returns a ‘good’ result for a tablet it is ‘locked-in’ as good, even if it then bounces onto an edge and so appears to be ‘bad’ in subsequent inspections. The vibratory feeders start and stop several times a minute and feed at varying rates to maximise the throughput into each bottle as the bottles index past. This continuous tracking of numerous tablets, with their associated inspection results, is a real accomplishment.

The Vision System has to find each tablet in each image, predict where it will be in the next image and match its new position and orientation in the new image to be able to identify it as the same tablet and so individually track it, building up its good / bad history.

The Vision System has to find each tablet in each image, predict where it will be in the next image and match its new position and orientation in the new image to be able to identify it as the same tablet and so individually track it, building up its good / bad history.

As the tablet leaves the tray and gets counted into a bottle the vision system outputs the tablet inspection result. The tablet must be deemed ‘good’ in at least one image, otherwise it is ‘bad’ and the bottle it goes into automatically gets segregate to a reject area.

Looking ahead

The machines described above are basically the standard PPS machines with minimal modifications to add machine vision. However the latest machine which MVT/PPS have just completed has been designed as a machine vision inspection system. It has a flat belt between the last vibrating tray and the output of the machine. This means the tablets are lying flat and are separated and it is also designed to reject individual tablets as they leave the belt. This system will inspect the tablets for width, length, area and colour in addition to thickness and will ensure only good product is discharged for further processing. This system can inspect up to 10,000 tablets per minute but is scalable to suit any application. To put this in perspective, a typical feed rate for the existing system is 2,500 tablets per min

Technologies used in this solution

For lighting MVT chose to use multiple LED arrays and selected Basler Scout GigeVision colour cameras for the image acquisition into one industrial PC. MVTec’s HALCON image processing software forms the basis of Machine Vision Technology’s customised C# application code.

These products are supplied and supported by Multipix Imaging.

http://multipix.com/casestudy/tablet-tracking-and-inspection/

01730 233332