Rapid Plant Changes for Rotating Products

Rapid Plant Changes for Rotating Products

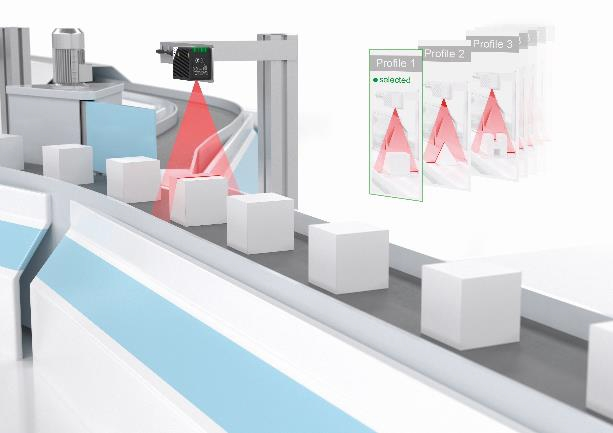

SmartRunner light section sensors are camera-based plug&play devices that users can easily commission without the need for specialist knowledge. The object to be detected is quickly recorded at the touch of a button using the teach-in functionality. The sensors then send a “good” or “bad signal” to their switching outputs and the signal can be processed by any control panel. The light section procedure delivers highly precise results and is suitable for detection tasks for which objects or process situations are characterized by height profiles and edge curves. Pepperl+Fuchs has recently added a new model to its SmartRunner range. Like the existing Matcher, the new model specializes in detection tasks using profile comparisons. This process includes detecting the presence, completeness and position of objects. A distinctive feature of the new Matcher is the ability to internally store up to 32 learned profiles. Switching between profiles and all of the corresponding settings is quick and easy thanks to the remote command offered by the integrated RS-485 interface. This feature is especially useful for businesses that frequently change their plants to account for different products and lots. Another interesting feature is the ability to detect a shift between the taught-in and current position of the object. This output offers important information regarding quality assurance and process safety, and allow defects to be corrected before actual failures arise. Using the SmartRunner technology, the Matcher can also be parameterized easily using Data Matrix control codes without the need for a PC. Gateways compatible with PROFINET, PROFIBUS, EtherCat or EtherNet/IP make it simple to connect the SmartRunner sensors to the latest fieldbus systems.